Steel Manufacturing in India: How It Works and What’s Next

Ever wondered how the massive steel towers you see on highways actually get made? It’s a mix of raw iron, huge furnaces, and a lot of expertise. In India, the steel story is especially interesting because the country balances old‑school blast furnaces with newer electric arc methods. Let’s break down the basics so you can see what’s behind those shiny beams.

Key Steps in Steel Production

The journey starts with iron ore, which is mined in places like Odisha and Jharkhand. The ore is crushed, washed, and then fed into a blast furnace where it meets coke and limestone. This burning combo turns the ore into molten iron.

Next, the molten iron moves to a basic oxygen furnace (or a converter) where oxygen is blown in. This strips away excess carbon and other impurities, turning the iron into crude steel. Some plants skip this step and use electric arc furnaces, especially when they recycle scrap metal. The advantage? Less energy use and lower emissions.

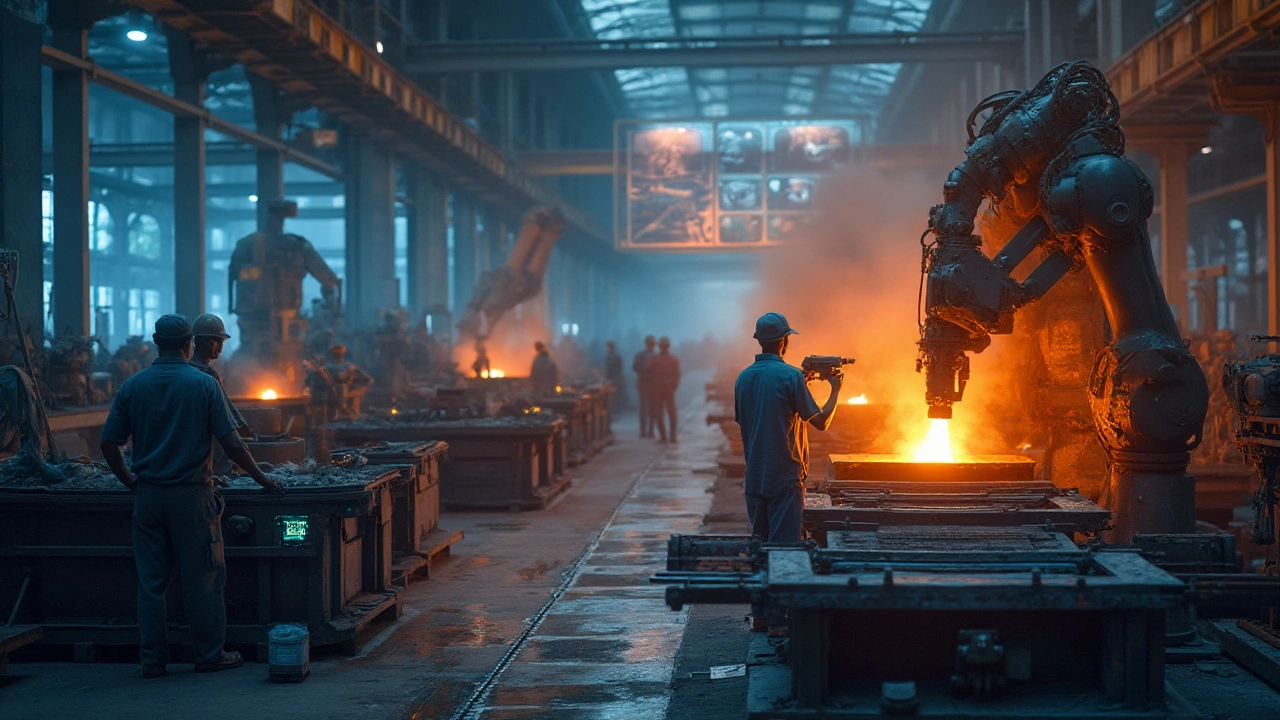

Once you have liquid steel, it’s poured into molds or rolled on huge rollers to create slabs, billets, or coils. These intermediate forms are later shaped into bars, beams, wires, or plates depending on the end use. The whole process is highly automated, but skilled engineers still monitor temperature, composition, and flow to keep the product consistent.

Trends Shaping the Future

India’s steel market is booming because of infrastructure projects, rail expansion, and a growing automotive sector. Companies like Tata Steel, JSW Steel, and the world’s biggest player ArcelorMittal India are racing to add capacity. Many are also investing in greener technology – think hydrogen‑based reduction or carbon capture – to meet stricter environmental rules.

Another big shift is the rise of “smart” steel plants. Sensors track every step, AI predicts maintenance needs, and data analytics help reduce waste. The result? Faster production, lower costs, and a cleaner footprint.

Finally, trade policies matter. Import duties on raw iron ore and steel affect pricing, while export incentives can boost demand overseas. Keeping an eye on government announcements can give you a clue about where prices are headed next.

So, whether you’re a contractor looking for reliable steel, an investor curious about the market, or just someone who enjoys knowing how everyday materials are made, the Indian steel scene offers plenty to watch. From traditional blast furnaces to cutting‑edge green tech, the industry is moving fast – and there’s never been a better time to understand what’s happening underneath those massive structures.

Why American Steel Is Often Preferred Over Chinese Steel in Critical Applications

American steel outperforms Chinese steel in critical applications due to stricter standards, better traceability, and consistent quality control - making it the safer, more reliable choice for infrastructure, medical devices, and heavy machinery.

Where is Steel Made in the US: Top Locations Uncovered

Discover where steel manufacturing thrives in the US, highlighting major production hubs in states like Indiana and Ohio. Uncover the history and modern advancements that keep these plants running efficiently. Learn about the significance of locations like Gary and Detroit in shaping the American steel landscape. Find out how renewable energy is transforming traditional steel plants, and what the future holds for this crucial industry.

Where Does the US Buy Most of Its Steel?

The US relies heavily on steel imports to fulfill its industrial and construction needs. Major sources include Canada, Mexico, and Brazil, with Canada often topping the list due to its proximity and established trade agreements. Understanding where the US sources its steel can reveal insights into trade relationships and economic influences. The article explores key suppliers, trade dynamics, and the impacts on the domestic market.

Who Supplies Ford's Steel? Discover Their Key Partners

Ford, known for its iconic vehicles, sources steel globally to ensure quality and sustainability. The company relies heavily on partnerships with major steel producers for key supplies. This article dives into the steel procurement strategy of Ford, highlighting major suppliers and the factors influencing these partnerships. Understanding these relationships reveals the complexity behind Ford's production process.

What US City Makes the Most Steel?

American cities have long been involved in steel production, but one city stands out as the top steel producer in the country. This article delves into the historical significance of America's leading steel city and explores how it maintains its dominant position today. Discover the economic impact of steel on local and national scales, along with an insight into modern manufacturing techniques that contribute to its success. Learn how workforce skills and technological advancements play a crucial role in the steel industry's continued growth.

The Leading Force: Who Dominates the Steel Industry?

The steel industry stands as a fundamental pillar in manufacturing, construction, and technology. In today's competitive landscape, determining who leads this colossal sector involves evaluating factors such as production capacity, innovation, and market influence. This article delves into the significant players currently shaping the steel world, offering insights into their strategies and achievements. It also explores the opportunities and challenges faced by these industry giants.

American Steel Production: A Resilient Industry on the Rise

American steel production remains a vital component of the country's industrial backbone. Although the industry has faced challenges, including international competition, it has adapted through innovation and sustainability efforts. This article explores the current state of steel manufacturing in the USA, offering insights into key players, technological advancements, and the future of the industry. Discover how American steel makers are balancing economic pressures with environmental responsibilities to maintain their competitive edge.

The Emerging Future of Steel: Innovations and Developments

As the world continues to industrialize and innovate, the demand for steel is undergoing significant changes. This article explores the evolving role of steel in the future, particularly how advancements in manufacturing processes are shaping its potential. Discover the revolutionary materials and technologies that promise to redefine steel's place in the industrial world. By looking at current trends and future predictions, we gain insight into how these transformations will impact both industrialists and everyday consumers.