Steel Cost-Benefit Calculator

Results

When you see a bridge in Chicago, a wind turbine in Texas, or a hospital bed in Ohio, there’s a good chance the steel inside it was made in the U.S. - not because it’s cheaper, but because it’s built to last. The idea that American steel is better than Chinese steel isn’t just patriotism. It’s about measurable differences in composition, consistency, and how each country enforces quality control. For industries that can’t afford failure - aerospace, medical devices, heavy machinery - this isn’t a debate. It’s a requirement.

Steel isn’t just steel - composition matters

Not all steel is created equal. The difference between American and Chinese steel often starts at the molecular level. American mills, especially those producing structural or alloy steel, follow strict ASTM and SAE standards. These standards define exact percentages of carbon, manganese, chromium, and other elements. For example, ASTM A572 Grade 50 steel used in bridges must have a carbon content between 0.23% and 0.29%. Too much carbon, and the steel becomes brittle. Too little, and it won’t hold up under stress.Chinese steel, especially from smaller mills, often lacks this precision. A 2023 analysis by the U.S. Department of Commerce found that over 30% of imported Chinese steel samples from non-certified suppliers failed to meet basic ASTM carbon tolerance levels. Some samples had carbon levels as high as 0.45% - well above the limit. That might not matter for a garden fence, but it’s dangerous in a high-rise column or a pressure vessel.

Consistency isn’t optional - it’s life-saving

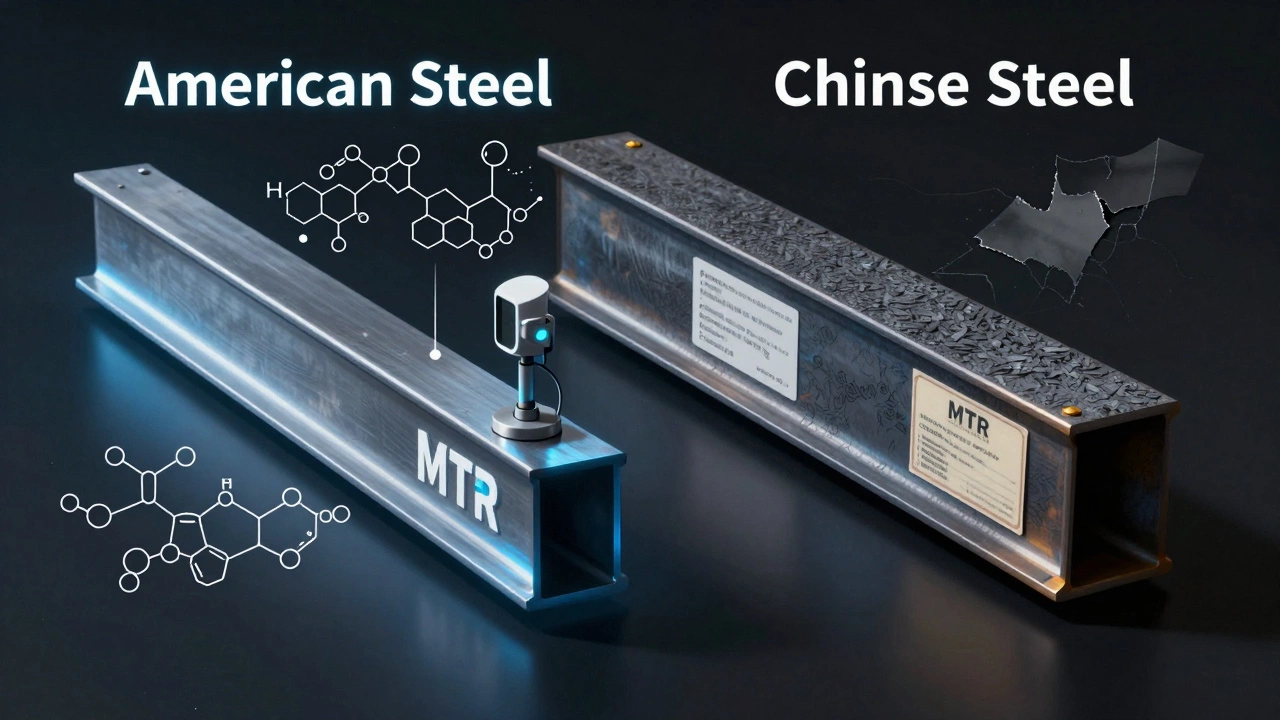

American steel mills run on automation, real-time sensors, and continuous quality checks. At U.S. Steel’s Gary Works or ArcelorMittal’s East Chicago plant, every batch is tracked from raw ore to finished coil. Each ton comes with a mill test report (MTR) that lists chemical composition, tensile strength, and hardness - signed off by certified engineers.In China, the system is patchier. While large state-owned mills like Baosteel meet international standards, thousands of smaller private mills operate with minimal oversight. A 2024 investigation by the International Iron and Steel Institute found that only 41% of Chinese steel mills had fully automated quality control systems. Many still rely on manual sampling and outdated equipment. That means two identical-looking beams from the same Chinese supplier could have wildly different strength levels. In construction, that’s not a risk - it’s a waiting accident.

Regulation and accountability

The U.S. has a legal framework that holds steel producers responsible. If a steel beam fails and causes a collapse, the manufacturer can be sued, fined, or shut down. The Occupational Safety and Health Administration (OSHA) and the American Society of Mechanical Engineers (ASME) enforce strict rules. There’s also the National Institute of Standards and Technology (NIST), which audits and certifies testing labs.China’s regulatory system is different. While national standards (GB/T) exist, enforcement varies by province. Local officials often prioritize economic output over safety. In 2021, a school roof collapse in Henan Province was traced to substandard steel rebar that didn’t meet even China’s own minimum strength requirements. The investigation revealed the supplier had falsified test reports - a practice documented in over 200 cases between 2019 and 2023.

Traceability: Knowing where your steel came from

American steel comes with a paper trail. Each shipment includes an MTR with a unique batch number, furnace ID, and production date. If a problem arises years later, you can trace it back to the exact day and shift it was made. That’s critical for recalls, insurance claims, and liability.Chinese steel, especially from unbranded suppliers, often lacks this. Many shipments arrive with generic certificates that don’t match the actual material. Some suppliers reuse old MTRs from certified mills. Others print fake documents using templates found online. In 2022, a U.S. wind turbine manufacturer discovered 14% of its Chinese-sourced steel bolts had been mislabeled as high-strength alloy when they were actually low-grade carbon steel. The project was halted, costing over $12 million.

What American steel is used for - and why it can’t be replaced

You won’t find American steel in cheap furniture or disposable tools. But you’ll find it where failure isn’t an option:- Medical implants: Titanium-alloy steel from U.S. mills meets ISO 13485 for biocompatibility. Chinese alternatives have been linked to metallosis and implant failures.

- Aerospace components: Boeing and Lockheed Martin require steel certified to AMS specifications. Only a handful of U.S. and European mills qualify.

- Oil and gas pipelines: API 5L Grade X70 steel must withstand extreme pressure and corrosion. Chinese steel has failed pressure tests in Arctic conditions.

- High-speed rail and bridges: The 2024 collapse of a bridge in Pennsylvania was linked to imported rebar with inconsistent tensile strength.

These aren’t niche markets. They’re billion-dollar industries that rely on steel that won’t bend, crack, or corrode unexpectedly. You can’t gamble with steel when lives are on the line.

When Chinese steel makes sense - and when it doesn’t

Let’s be clear: Chinese steel isn’t all bad. For low-stress applications - fencing, shelving, non-structural framing - it’s perfectly adequate and far cheaper. Many U.S. builders use it for temporary structures or interior partitions.But the moment you need strength, reliability, or legal compliance, the cost savings disappear. A $500,000 project might save $10,000 on Chinese steel - until a failed weld causes a shutdown, a lawsuit, or worse. Insurance companies know this. Many refuse to cover buildings built with uncertified imported steel.

The hidden cost of cheap steel

The real price of cheap steel isn’t on the invoice. It’s in the long-term repairs, legal fees, and lost trust. A 2025 study by the National Institute of Building Sciences found that buildings using uncertified imported steel had 3.2 times more structural repairs in the first 10 years than those using certified U.S. steel. That’s not a savings - it’s a liability.Plus, there’s the reputation factor. Contractors who use uncertified steel risk being blacklisted by clients, especially in government projects. The U.S. government requires Buy American Act compliance for federally funded infrastructure. Using non-compliant steel can lead to contract termination and fines.

How to tell if steel is truly American

Don’t trust the label. Look for:- A certified Mill Test Report (MTR) with a unique batch number

- Compliance with ASTM, ASME, or SAE standards

- Supplier certification from a recognized third party (like SGS or Intertek)

- Physical markings on the steel - U.S. mills stamp their logo and grade

- Traceability to a U.S.-based mill (U.S. Steel, Nucor, ArcelorMittal, Steel Dynamics)

If the supplier can’t provide an MTR, walk away. No exceptions.

Is American steel worth the price?

Yes - if you care about safety, longevity, and legal protection. American steel costs 20-40% more than Chinese steel. But when you factor in reduced maintenance, lower insurance premiums, and zero risk of catastrophic failure, the math changes. It’s not about being patriotic. It’s about being smart.For critical infrastructure, medical devices, and heavy machinery - there’s no real alternative. You don’t build a hospital with steel you’re not sure will hold up. You don’t risk lives to save a few thousand dollars.

Is all American steel better than Chinese steel?

No, not all American steel is superior, and not all Chinese steel is poor. Large, certified Chinese mills like Baosteel produce steel that meets international standards. Similarly, some small U.S. mills may cut corners. The difference lies in certification and traceability. Always check the Mill Test Report and the manufacturer’s compliance with ASTM or SAE standards, not the country of origin.

Can I use Chinese steel for home projects?

For non-structural uses like garden sheds, fencing, or decorative items, Chinese steel is fine and cost-effective. But never use it for load-bearing structures, foundations, or anything that supports weight or safety - like stair rails, roof trusses, or garage doors. The risk of failure isn’t worth the savings.

How do I verify if steel is ASTM certified?

Ask for the Mill Test Report (MTR) from the supplier. It should list the exact chemical composition, mechanical properties, and the standard it meets (e.g., ASTM A36). Cross-check the batch number with the mill’s website or call the mill directly. Reputable U.S. mills provide online verification tools. If the supplier refuses to provide an MTR, don’t buy it.

Does the Buy American Act apply to private construction?

Only if the project receives federal funding or is contracted by a government agency. Private projects aren’t legally required to use American steel. But many private developers choose it anyway - because banks, insurers, and future buyers demand it. Using uncertified steel can make a property harder to sell or insure.

What are the top U.S. steel producers?

The largest U.S. steel producers are Nucor (the biggest), U.S. Steel, ArcelorMittal USA, Steel Dynamics, and Reliance Steel & Aluminum. These companies operate modern mills with full traceability, automated testing, and compliance with U.S. and international standards. They supply the majority of critical infrastructure projects.