When we think about steel production in the US, big names usually pop up like Pittsburgh, which was historically dubbed the 'Steel City.' However, if we're talking about today, most folks might be surprised to learn that it's not Pittsburgh topping the charts. The city leading the pack right now is Sterling Heights, Michigan. Yup, it may not have the same ring to it as Pittsburgh, but it's where the steel is churning out in massive quantities.

You might be wondering how Sterling Heights managed this feat. Well, it all ties into the region's industrial roots and the local expertise that's been honed over years. The city's geographical location also plays a role, nestled in a zone teeming with manufacturing activity. But geographical perks aren't the only factor; the city's production lines have embraced technology like nowhere else—think automation and cutting-edge robotics.

Besides raw numbers, what's fascinating is the ripple effect this industry has on the local economy. Jobs created, businesses supported, and tax revenues generated make a considerable impact. And with the way the steel industry supports sectors from construction to automotive, its reach extends far beyond just numbers and figures.

- A Brief History of Steel in America

- The Top Steel-Producing City

- Economic Impact of Steel

- Modern Manufacturing Techniques

- Future of Steel Production

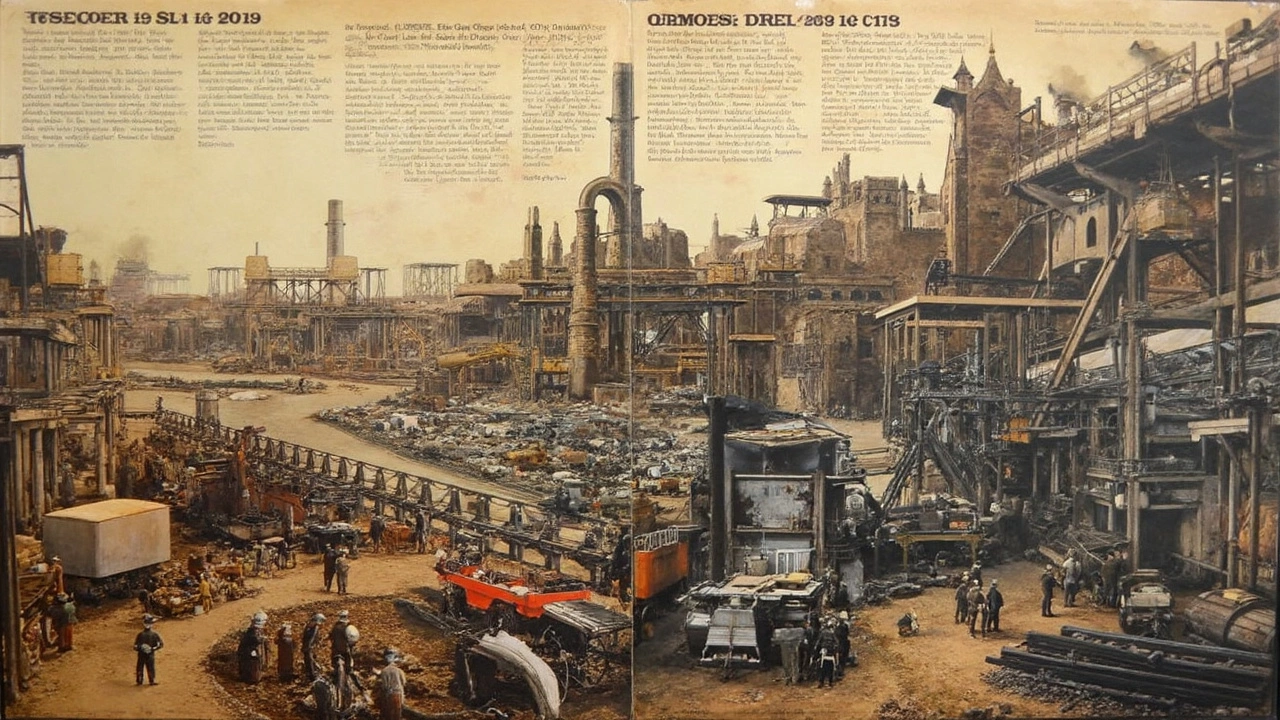

A Brief History of Steel in America

The story of steel in America is pretty fascinating, and it dates back to the mid-19th century. It all started when America was on a mission to catch up with Europe's steel-making capabilities. Initially, the focus was on small-scale production, but things changed with the discovery of rich iron ore deposits in places like the Great Lakes region.

Andrew Carnegie, a name you might recognize, was a huge player in putting the US on the world map in terms of steel production. In the late 1800s, he built a number of steel plants that capitalized on the latest technologies, which at the time meant the Bessemer process. By doing this, he helped transform small towns into powerhouse industrial hubs in cities like Pittsburgh, setting the stage for the steel boom.

The Golden Era

Fast forward to the early 20th century, and US steel production was thriving. World Wars I and II drove high demand for steel, which was crucial for ships, weapons, and vehicles. American steel plants were working at full steam, contributing massively to the war efforts and beyond, fueling America’s economic engine well into the mid-century.

Challenges and Adaptations

However, the good times didn’t last forever. The 1970s and 1980s were tough for the American steel industry, largely due to increased competition from abroad and rising operational costs. Many plants struggled or shut down entirely, leading cities like Pittsburgh, once famous for its steel, to diversify their economies.

But don’t count America out. Modern times brought modernization and efficiency improvements. Places like Sterling Heights are proving that with the right technological embrace, the industry can still thrive. Today, despite global challenges, steel remains an important part of the American industrial landscape, continuing to evolve and adapt as it has for over a century.

The Top Steel-Producing City

Sterling Heights, Michigan, might not be the first place you think of when talking about steel production, but this city has quietly climbed to the top. Its rise as the leading steel hub in the United States is a mix of historical, geographical, and technological factors. Let’s dig deeper into why this city holds the crown.

Historical Background

Originally known more for its automotive industry, Sterling Heights shifted gears over the past few decades. The auto industry itself has heavy reliance on steel, so the existing infrastructure and skilled workforce naturally led to the city's expansion in steel manufacturing. Local expertise helped build robust facilities that produce high-quality products.

Strategic Location

Nestled in the northeastern industrial belt, Sterling Heights benefits from a location rich in resources and connectivity. Proximity to the Great Lakes offers easy access to transport raw materials and finished goods. Combine this with a diversified industrial landscape, and you see why steel production is thriving here.

Technological Advancements

Sterling Heights harnesses the latest in tech to ramp up production efficiently. Modern facilities have adopted automation and robotics, making the production process faster and more reliable. The city’s drive towards sustainable steel manufacturing also draws attention, reducing the environmental impact while boosting output.

Economic Impact

The steel industry isn't just about making steel; it's a cornerstone of the local economy. It generates thousands of jobs directly in the mills and indirectly in related sectors. This economic heartbeat supports everything from local businesses to infrastructure development.

| Year | Steel Output (in million tons) |

|---|---|

| 2023 | 8.4 |

| 2024 | 9.1 |

| 2025 (Projected) | 9.8 |

These numbers show a clear upward trend, proving the city's enduring prominence in the steel manufacturing industry.

Economic Impact of Steel

When discussing the American steel production landscape, we can't ignore the massive economic footprint it leaves. Cities like Sterling Heights lead the charge, and the benefits ripple through their economy like waves crashing on a busy shore.

First up, jobs. The steel industry is a significant employer, and not just on the production floor. We're talking about thousands of workers involved in everything from transport logistics to engineering and management. In Sterling Heights alone, steel production supports a substantial chunk of local employment, empowering communities with steady, reliable jobs when those aren't always easy to come by.

Beyond jobs, there's the network of local businesses that thrive from steel operations. Think suppliers who provide raw materials, contractors who build and maintain the facilities, and even caterers ensuring workers stay fueled during long shifts. Each plays a crucial role. The local economy expands, and as factories pick up the pace, they pull the whole professional ecosystem along for the ride.

National Scale and Revenue

On a national level, steel's economic punch is even more pronounced. The US regularly churns out millions of metric tons of steel annually. According to the American Iron and Steel Institute, the steel industry contributes nearly $520 billion to the economy and accounts for over 2 million jobs nationwide. It's a big number that showcases just how vital this sector is.

Additionally, steel manufacturing bolsters the US's position in global trade. While imports play their part, the ability to produce homegrown steel strengthens the country's competitive edge on the global stage, powering everything from skyscrapers to automobiles efficiently and cost-effectively.

In terms of tax revenue, steel plants bring considerable money to both state and federal government coffers. This income funds infrastructure projects, schools, healthcare—services that truly matter to everyday folks living in these hubs.

Challenges and Opportunities

But like any story with ups, there are downs too. Tariffs, international competition, and fluctuating demand can all present challenges. However, with challenges come opportunities for innovation, efficiency improvements, and environmental considerations that help shape the industry for future generations.

In a nutshell, the economic impact of steel spans various facets of life, ensuring that whether you're driving a car, sitting in a skyscraper, or even just hanging out at home, the industry’s influence is never far off.

Modern Manufacturing Techniques

In today's world, steel manufacturing is a far cry from the sooty, labor-intensive processes of yesteryear. The game-changer? Technology. By embracing automation and innovative techniques, cities like Sterling Heights have sprinted ahead in the steel production race.

Automation and Robotics

One major development is the use of automation on the production line. Imagine robots with precision-like focus, performing tasks that once required human hands. This doesn't just mean faster production, but also less room for error. In fact, some factories have cut down production time by nearly 50%. Talk about efficiency!

Advanced Techniques

Modern steel plants aren't just about churning out metal; they're about doing so with amazing new techniques. For instance, Electric Arc Furnaces (EAF) are a big thing now. Instead of starting from scratch with raw materials, these bad boys reuse scrap steel. It's both time-saving and environmentally friendly—win-win, right?

Data-Driven Decisions

The role of data can't be overstated. Imagine having real-time analytics guiding each decision on the floor. It’s like having a GPS for the steel manufacturing process. This reduces wastage and helps allocate resources where they're most needed.

Here’s an example showing how data is transforming steel production:

| Aspect | Traditional Methods | Data-Driven Methods |

|---|---|---|

| Resource Allocation | Manual estimation | Real-time analytics |

| Production Timeline | Fixed schedule | Dynamic adjustments |

| Quality Control | Human inspection | Machine learning algorithms |

The Road Ahead

Sterling Heights continues to leverage these technologies, and with them, it’s on pace to maintain its status as a frontrunner in steel manufacturing. These advancements don’t only make the city an industrial giant; they also provide lessons for other cities looking to revamp their own production lines.

Future of Steel Production

The world of steel is headed towards some exciting changes, and cities like Sterling Heights are at the forefront of this evolution. With the global push towards sustainability, the steel manufacturing industry is looking for ways to reduce its carbon footprint. That's a big deal because traditional steelmaking processes are notorious for high emissions. The future is all about cleaner, more energy-efficient methods of production.

One trend that's gaining traction is the use of electric arc furnaces (EAFs). Unlike the old-school blast furnaces, EAFs use electricity to melt scrap steel, which is not only more energy-efficient but also relies less on raw material extraction. This shift is great news for the environment and offers cities a chance to boost local economies through recycling.

Innovation and Technology

Technology is playing a central role in the industry's transformation. Steel plants are increasingly incorporating automation and artificial intelligence to optimize production processes. This isn't just about fancy robots; it's about using precise data analytics to predict equipment maintenance, which reduces downtime and increases efficiency.

There are even experiments with 3D printing in steel manufacturing. Imagine being able to create complex components with less waste and in less time. That's the kind of innovation we're talking about, and it could redefine what's possible in American cities known for industrial output.

Global Competition and Demand

While innovation is key, US cities have to keep an eye on global competition as well. Countries like China and India are ramping up their production capabilities, so staying ahead involves not just embracing new tech but also adapting to changing market demands. That means exploring new steel products or catering to emerging technologies, like electric vehicles, that require higher-quality steel.

Overall, the future of steel production feels bright, especially for US cities like Sterling Heights known for their industrial prowess. By continuing to innovate and prioritize sustainability, they can maintain their leading position in the global steel market while contributing to a greener world.