Code 5 Plastic Information Finder

What Is Code 5 Plastic?

Code 5 plastic refers to polypropylene (PP), a versatile thermoplastic polymer. It's known for its heat resistance, chemical resistance, and durability.

Resin ID: 5Common Uses of Code 5 Plastic

- Food Packaging (yogurt cups, deli containers)

- Automotive Parts (battery cases, bumpers)

- Medical Devices (syringes, sterile packaging)

- Textiles (rope, carpets)

- Industrial Applications (storage bins, pallets)

Recycling Process

- Collection: Separate items with the recycling symbol containing "5"

- Sorting: Identify polypropylene using optical sorters

- Cleaning: Remove food residue and contaminants

- Shredding: Cut into small flakes

- Re-melting & Extrusion: Transform flakes into pellets for reuse

Recycling Rate: Around 15-20% globally, lower than PET (1) or HDPE (2).

Safety & Environmental Impact

- Approved for food contact by EFSA and FDA

- No harmful leaching (BPA, phthalates)

- Lower carbon footprint than PET and PVC

- Not biodegradable; persists in landfills for centuries

- Burning releases toxic fumes – avoid home incineration

When you see the number 5 inside the triangular recycling symbol on a bottle or container, you’re looking at code 5 plastic - a material most people know as polypropylene. It’s cheap, tough, and shows up in everything from yogurt cups to automotive parts. This guide breaks down what code5 plastic is, why it matters, and how you can handle it responsibly.

Key Takeaways

- Code5 plastic is the resin identification code for polypropylene (PP), a versatile thermoplastic.

- It resists heat, chemicals, and fatigue, making it ideal for packaging, automotive, and medical uses.

- Recycling rates for code5 are lower than PET (code1) or HDPE (code2) but are improving with new technologies.

- Look for the recycling symbol with the number 5 to sort items correctly.

- When recycling isn’t available, reuse or up‑cycle code5 items to extend their life.

What Is Code5 Plastic?

Code5 plastic belongs to the family of polypropylene (PP), a semi‑crystalline thermoplastic polymer. The International Organization for Standardization (ISO) introduced the Resin Identification Code (RIC) in 1988, assigning numbers 1-7 to the most common plastics. The goal was to help consumers separate waste for recycling. Code5 specifically points to polypropylene, which has a melting point of about 160‑170°C (320‑338°F) and a density around 0.90g/cm³.

Physical and Chemical Properties

Understanding the material’s properties clarifies why it’s everywhere:

- Heat resistance: Can tolerate boiling water and microwave heating without deforming.

- Chemical resistance: Stands up to acids, bases, and most solvents.

- Flexibility and toughness: Offers a good balance between rigidity and bendability.

- Low moisture absorption: Keeps its shape and strength even in humid environments.

These traits make polypropylene the go‑to choice for containers that need to keep food fresh, parts that must endure repeated stress, and medical devices that demand sterilization.

Common Applications of Code5 Plastic

Here’s a quick snapshot of where you’ll encounter code5 items:

| Product Category | Examples | Why PP Fits |

|---|---|---|

| Food Packaging | Yogurt cups, deli containers, bottle caps | Heat‑stable, barrier to moisture, safe for microwave |

| Automotive | Battery cases, interior trim, bumpers | Durable, lightweight, resists chemicals |

| Medical | Syringe barrels, medical tubing, sterile packaging | Can be sterilized, inert to bodily fluids |

| Textiles | Rope, carpets, non‑woven fabrics | Strong, resistant to wear and UV |

| Industrial | Plastic hinges, pallets, storage bins | High impact resistance, low cost |

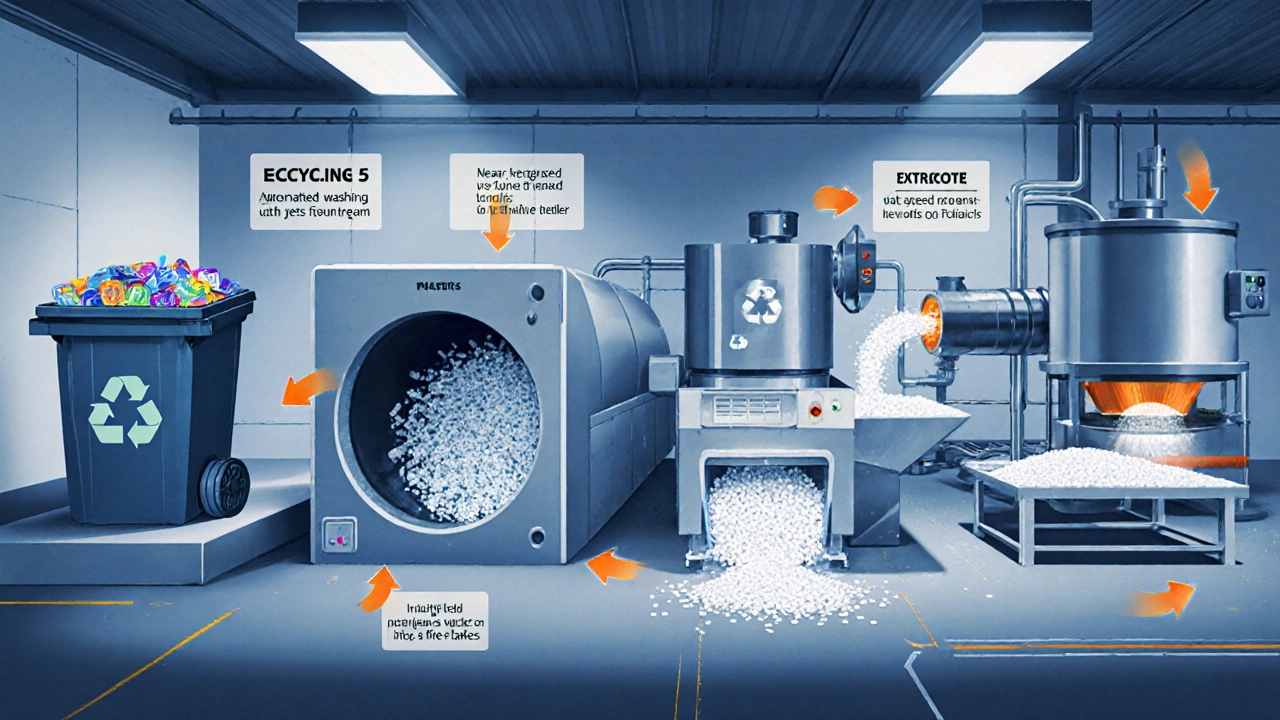

How Is Code5 Plastic Recycled?

Recycling polypropylene is more challenging than PET (code1) or HDPE (code2) because the market for recycled PP is smaller and the material often contains additives that complicate re‑processing. Still, the steps are similar:

- Collection: Households or businesses separate items bearing the “5” inside the recycling triangle.

- Sorting: Automated optical sorters or manual stations identify the resin code.

- Cleaning: Items are washed to remove food residues and contaminants.

- Shredding: Clean pieces are ground into flakes.

- Re‑melting and Extrusion: Flakes are melted and extruded into pellets for new products.

In the UK, the most common end‑uses for recycled PP include landscaping timbers, automotive components, and reusable containers. However, the overall recycling rate hovers around 15‑20%, far below the 60‑70% rates for PET and HDPE.

Improving the Recycling Loop

Several initiatives are pushing the numbers up:

- Advanced sorting technology: Near‑infrared (NIR) sensors can differentiate PP from other plastics with 95% accuracy.

- Design for recyclability: Manufacturers are reducing colored additives and multi‑layer laminates that hinder re‑processing.

- Closed‑loop programs: Brands like Coca‑Cola and Nestlé run take‑back schemes for their PP bottles.

If you want to help, check local council guidelines-some areas accept PP in curbside bins, while others require drop‑off at dedicated facilities.

Environmental Impact Compared to Other Plastics

Polypropylene’s carbon footprint is lower than many alternatives. Producing 1kg of PP emits roughly 1.7kg of CO₂, compared to 2.5kg for PET and 3.2kg for PVC (code3). Its lighter weight also reduces transportation emissions. However, the low recycling rate means a lot ends up in landfills, where it can persist for centuries.

Safety and Regulatory Aspects

Because PP is chemically inert, it’s approved for food contact by the European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA). It does not leach BPA, phthalates, or other harmful plasticizers. In medical contexts, PP meets ISO10993 standards for biocompatibility, which is why it’s used for syringes and IV containers.

On the downside, burning polypropylene releases toxic fumes (including carbon monoxide and polycyclic aromatic hydrocarbons). Never incinerate PP at home; rely on licensed waste‑to‑energy facilities that control emissions.

Tips for Consumers: How to Handle Code5 Items

- Check the symbol: Look for the “5” inside the recycling triangle.

- Know your local rules: Some councils accept PP with other plastics, while others require separate drop‑off.

- Reuse first: Turn a sturdy PP container into a storage jar, plant pot, or DIY organizer.

- Clean before recycling: Rinse food residue to improve the quality of the recycled batch.

- Support recycled‑content products: Choose goods that list “recycled polypropylene” on the label.

Future Trends for Code5 Plastic

Research is focusing on two main fronts:

- Biodegradable alternatives: New bio‑based polypropylene blends aim to retain performance while breaking down faster after use.

- Circular economy models: Companies are offering “take‑back” services, collecting used PP packaging to remanufacture high‑value items like automotive interior parts.

These trends suggest that while code5 plastic will stay in the market for years, its environmental footprint could shrink dramatically.

Frequently Asked Questions

What does the number 5 on the recycling symbol mean?

It identifies the material as polypropylene (PP), the polymer that carries the resin identification code 5.

Is code5 plastic safe for food contact?

Yes. Both the EU’s EFSA and the U.S. FDA have approved polypropylene for direct food contact because it does not leach harmful chemicals.

Can I recycle polypropylene at home?

It depends on your local council. Some areas accept PP in curbside bins; many still require you to drop it off at a recycling centre that handles code5.

What are common products made from code5 plastic?

Yogurt cups, bottle caps, food‑service trays, automotive battery cases, medical syringes, rope, and reusable storage bins are all typical PP items.

Why is polypropylene recycling less common than PET?

The market for recycled PP is smaller, and many PP products contain additives that make re‑processing harder. New sorting technologies are helping to close that gap.