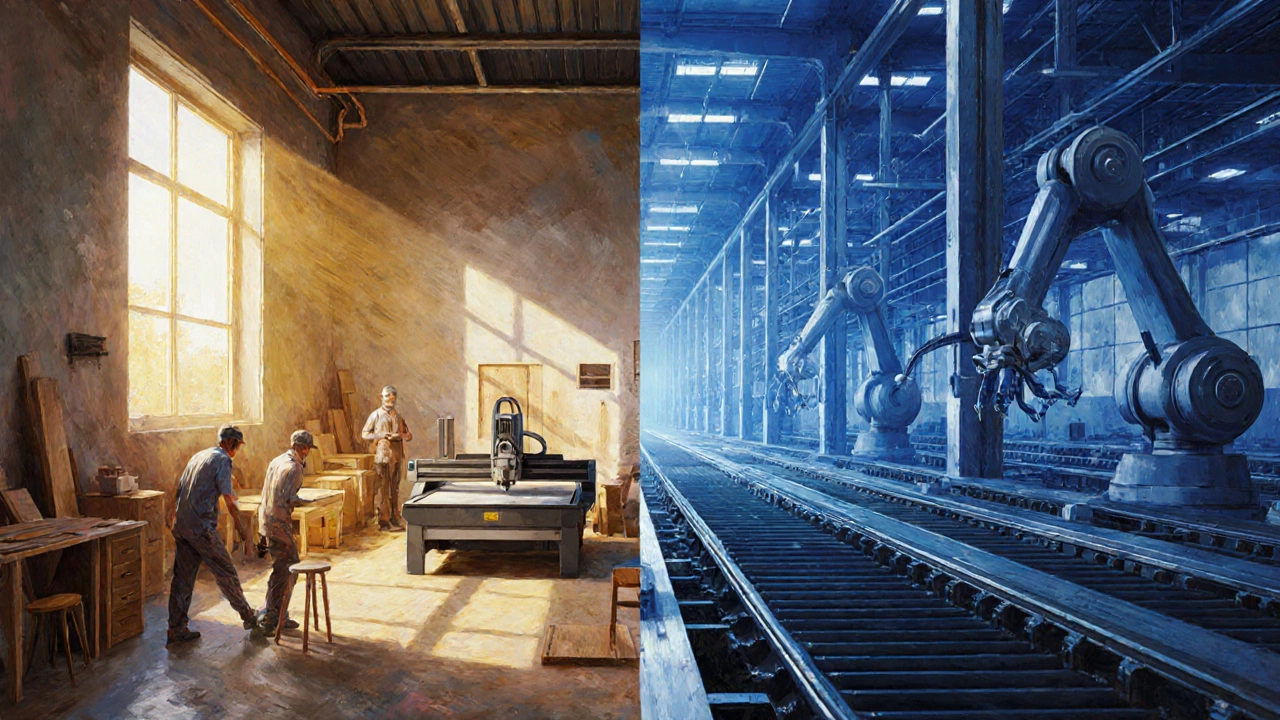

When people talk about small scale manufacturing is a production approach that operates with limited capital, modest output volumes, and a focus on flexibility rather than mass output, they’re highlighting a niche that sits between artisanal workshops and giant factories. Think of a local brewer crafting a few thousand bottles a month, or a family‑run metal shop churning out custom parts for nearby farms. This model lets entrepreneurs stay close to their customers, adapt quickly, and keep overhead low.

What Exactly Is Small Scale Manufacturing?

At its core, small scale manufacturing refers to the creation of goods using production capacities typically under 10,000 units per year, limited floor space, and modest machinery. The exact thresholds vary by industry and country, but the common thread is a business that can be managed by a small team-often fewer than 50 employees-and that doesn’t require the massive supply‑chain networks of large‑scale plants.

In contrast, large scale manufacturing involves high‑volume production, extensive automation, and substantial capital investment, often exceeding millions of pounds. Understanding this distinction helps you decide which path fits your vision, budget, and market goals.

Key Characteristics to Spot

- Production volume: Usually under 10,000 units annually, though some niche sectors count in tens of thousands.

- Capital investment: Often less than £500,000 for equipment and facilities, making financing easier.

- Workforce size: Typically 1‑50 staff, allowing owners to wear many hats.

- Flexibility: Ability to switch product lines or customize orders quickly.

- Local supply chain: Relies on nearby suppliers, reducing transport costs.

Why Choose Small Scale Manufacturing?

There are several compelling reasons to go small. First, the lower upfront costs mean you can test a product idea without risking a fortune. Second, being close to customers enables rapid feedback loops-if a design flaw pops up, you can fix it before a massive batch is produced. Third, many governments view small manufacturers as engines of employment and innovation, so they often roll out government schemes such as grants, low‑interest loans, and tax incentives aimed at micro‑ and small‑enterprise (MSME) sectors.

Real‑world examples illustrate the power of scale. In Manchester, a boutique furniture maker started with a single CNC router and now supplies contract offices across the North West. In Kerala, India, a small spice‑blending unit uses family‑owned milling equipment to export premium masalas worldwide, leveraging the “Make in India” MSME support.

Potential Drawbacks to Keep in Mind

Small scale isn’t a free‑for‑all. Limited production capacity can make it tough to meet large orders, and economies of scale mean per‑unit costs are higher than in massive plants. Access to advanced automation may be out of reach, and scaling up later can require a complete overhaul of processes and equipment.

Typical Sectors That Thrive on Small Scale

Many industries naturally lend themselves to a smaller footprint:

- Food processing (artisan cheese, craft beverages, specialty sauces)

- Textile manufacturing (hand‑loom fabrics, custom prints)

- Metal fabrication (precision brackets, agricultural tools)

- Plastic molding (low‑volume injection molds for medical devices)

- Electronics assembly (custom PCBs, prototype gadgets)

How to Launch Your Small Scale Manufacturing Business

- Validate the market. Talk to potential buyers, run a small pilot, and confirm willingness to pay.

- Draft a concise business plan. Outline product specs, target market, cost structure, and break‑even analysis.

- Secure financing. Explore bank loans, micro‑finance, or government schemes like the UK's Small Business Grant Fund.

- Choose a location. Prioritize proximity to suppliers and customers; many start in converted commercial units or industrial sheds.

- Acquire equipment. Based on your production capacity needs, decide between buying second‑hand machinery or leasing.

- Hire the right team. For a crew under 20, look for versatile staff who can handle multiple roles.

- Implement quality control. Even small runs need consistent standards-set up SOPs, inspection checklists, and basic testing equipment.

- Launch and iterate. Start with a soft rollout, collect feedback, and tweak processes before scaling.

Government Support You Shouldn't Miss

Across the UK, several programs are tailored for small manufacturers:

- Innovate UK Smart Grants: Up to £2million for R&D that can improve production efficiency.

- Manufacturing Advisory Service (MAS): Free consultancy on process optimisation.

- Local Enterprise Partnerships (LEPs): Offer region‑specific grants and mentorship.

Eligibility usually hinges on annual turnover (under £10million) and employee count (under 50). Keep records tidy, as applications often demand projected cash flows and proof of market demand.

Quick Start Checklist

- Clear product definition and market need

- Feasibility study with cost‑per‑unit breakdown

- Financing plan (including possible grant sources)

- Suitable premises with adequate utilities

- Equipment list with purchase/lease options

- Health & safety compliance checklist

- Quality control SOPs ready before first run

- Marketing & sales channel strategy

Frequently Asked Questions

How many employees can a small scale manufacturer have?

Typically up to 50 staff, though some definitions push the limit to 100 if the turnover remains below the SME threshold.

What is the usual capital requirement?

Most start‑ups launch with £100,000‑£500,000, covering lease, basic machinery, and initial raw material stock.

Can I qualify for UK government grants as a sole trader?

Yes, many grants accept sole traders provided the business meets turnover and employment criteria. You’ll need a solid business plan and evidence of innovation or job creation.

What are the biggest risks for small manufacturers?

Cash‑flow gaps, supply‑chain disruptions, and difficulty meeting large orders are top concerns. Mitigate by maintaining a buffer stock, diversifying suppliers, and being transparent with customers about lead times.

How does quality control differ from large factories?

Smaller operations rely on manual inspections and simple testing rigs rather than automated vision systems. Though less high‑tech, a disciplined SOP and regular audits can achieve comparable defect rates.

Small vs. Large Scale: A Quick Comparison

| Aspect | Small Scale | Large Scale |

|---|---|---|

| Annual Output | Under 10,000 units | Hundreds of thousands to millions |

| Capital Investment | £100k‑£500k | £5million+ |

| Workforce | 1‑50 employees | 200+ employees |

| Flexibility | High - quick product changes | Low - long re‑tooling times |

| Supply Chain | Local, fewer tiers | Global, multi‑tiered |

| Regulatory Burden | Moderate - specific to sector | High - extensive reporting |

Choosing the right scale depends on your product, market demand, and resources. For many innovators, starting small provides a safe sandbox to refine ideas before considering expansion.