Innovation Driving India's Manufacturing Future

When you hear the word "innovation," you probably picture high‑tech labs or shiny new gadgets. In reality, innovation lives on the factory floor, in the supply chain, and even in the rules that govern what we can build. India’s manufacturing scene is buzzing with fresh ideas that cut costs, boost quality, and open up new markets. This page pulls together some of the most interesting stories that show how innovation is changing the game.

Why Innovation Matters Across Sectors

Every industry you read about here—pharmaceuticals, steel, furniture, textiles—has a different challenge, but they all share a common goal: do more with less. For pharma, it’s about scaling up production without compromising safety. In steel, it’s finding cheaper ways to melt iron while trimming waste. Furniture makers are experimenting with local wood species and modular designs to speed up delivery. The common thread is simple: smarter processes lead to higher profits and a stronger competitive edge.

Real‑World Examples You Can Learn From

Take the story of Indian pharmaceutical factories that now export a larger share of the world’s generic medicines. They cut costs by adopting continuous manufacturing lines, which keep the product moving without stopping for batch checks. The result? Lower prices for patients abroad and a bigger market share for Indian firms.

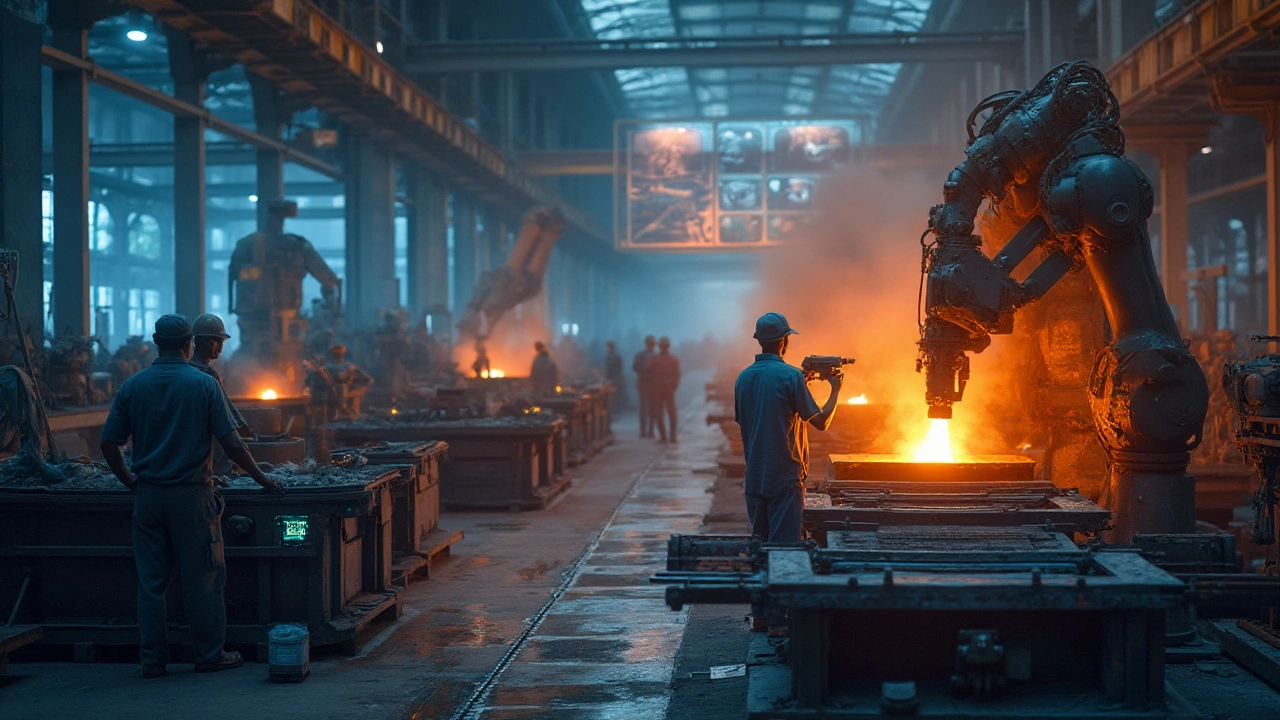

In the steel world, the shift from traditional blast furnaces to electric arc furnaces (EAF) is a clear innovation win. EAFs use recycled scrap instead of pure iron ore, slashing energy use by up to 30 %. Companies that made the switch are seeing lower carbon footprints and faster turnaround times.

Furniture designers are tapping into India’s rich timber resources, but they’re not just chopping trees. They’re using the "Mom method"—a set of simple steps that map out every stage of production, from raw wood selection to final assembly. This method helps them spot bottlenecks early, reduce material waste, and deliver finished pieces to customers in record time.

Even the rules can spark innovation. The recent ban on BS4 diesel engines forced manufacturers to upgrade to BS6 standards. While the transition required hefty investment, it also pushed companies to explore hybrid technologies and cleaner fuel options, opening doors to new product lines and greener branding.

Finally, look at the rise of smart imports. Data shows that countries supplying machinery to the US are now offering IoT‑enabled equipment that can report performance stats in real time. Indian firms that tap into this trend can offer maintenance‑as‑a‑service, turning a simple sale into an ongoing revenue stream.

All these stories underline a simple truth: innovation isn’t a one‑off event. It’s a habit of constantly testing, learning, and adapting. Whether you run a small textile workshop or a large steel plant, the same mindset applies—find the weak link, experiment with a new approach, and measure the results.

Ready to bring some of these ideas into your own operation? Start by asking: Which step in my production line wastes the most time or material? Then look for a tech or process change that can fix it. The answers are often closer than you think, hidden in the daily routines of your team.

Keep exploring, keep asking questions, and you’ll see how each small tweak adds up to big gains. Innovation is a journey, not a destination, and India’s manufacturing sector is already on the fast lane.

Innovative Products That Could Revolutionize Manufacturing

The manufacturing world thrives on innovation, yet there are still unexplored ideas waiting to become reality. Imagine the possibilities with smart fabrics that adapt to the weather, personalized health monitoring wearables, and eco-friendly packaging. Exploring the gap between today's technology and future needs can spark the next big manufacturing idea. Dive into these concepts and discover how untapped products could shape the industry.

Pioneers in Electronics Manufacturing: A Look at Leading Nations

Exploring which country leads in the realm of electronics manufacturing reveals fascinating insights about technological innovations and industry leaders. India, among others, has been making remarkable progress. This article delves into the key players in electronics and highlights their strengths. It provides a clearer understanding of the current electronics manufacturing landscape.

The Emerging Future of Steel: Innovations and Developments

As the world continues to industrialize and innovate, the demand for steel is undergoing significant changes. This article explores the evolving role of steel in the future, particularly how advancements in manufacturing processes are shaping its potential. Discover the revolutionary materials and technologies that promise to redefine steel's place in the industrial world. By looking at current trends and future predictions, we gain insight into how these transformations will impact both industrialists and everyday consumers.