Future Metal – What’s Coming Next in Metal Production

If you’ve ever wondered where the metal you see in cars, buildings or smartphones will come from in the next decade, you’re not alone. The metal world is buzzing with new alloys, cleaner processes and digital tools that promise to cut cost, waste and carbon. Below we break down the biggest changes you’ll see on the shop floor and why they matter to anyone who buys or works with metal.

Green Steel and Low‑Carbon Processes

Traditional steelmaking releases a lot of CO₂, but today more plants are switching to electric arc furnaces that run on renewable electricity. This shift, often called “green steel,” can cut emissions by up to 70% compared with coal‑based blast furnaces. Companies in India, the US and Europe are already rolling out pilots, and many have set 2030 targets to reach net‑zero. For the average buyer, that means cheaper, more eco‑friendly steel that meets tighter regulations without sacrificing strength.

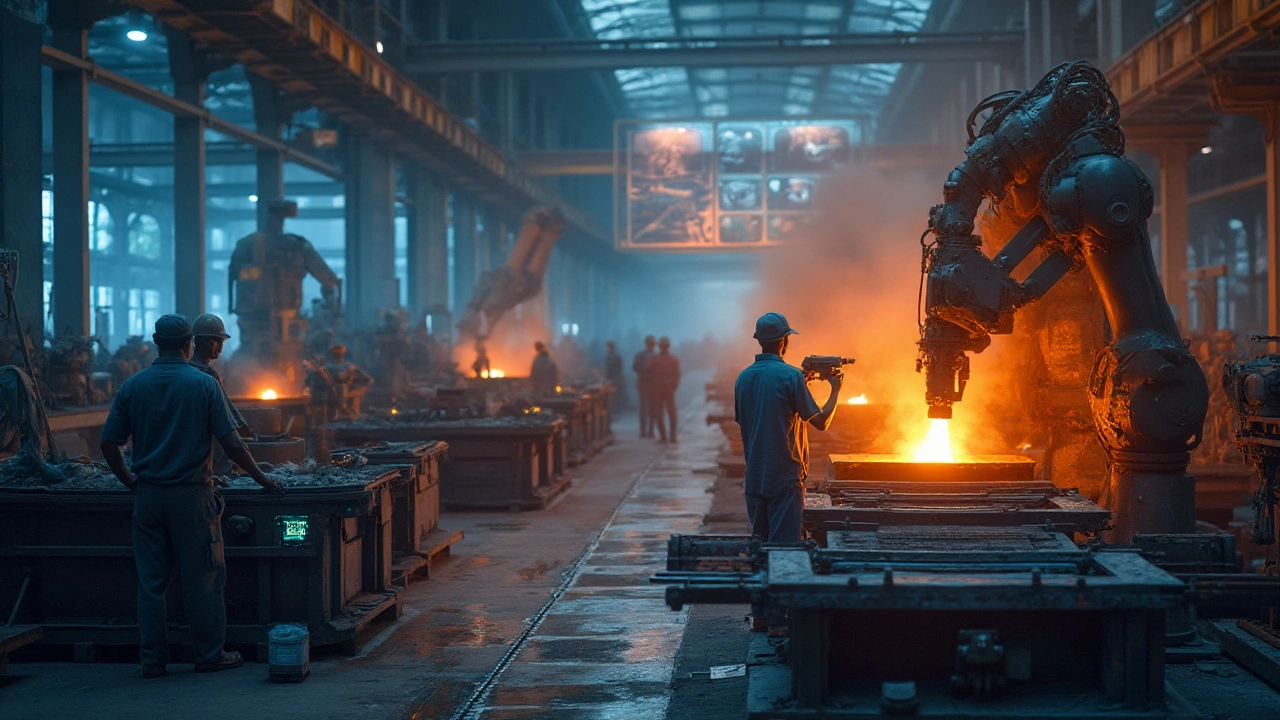

Smart Factories and AI‑Driven Quality

Factory floors are getting smarter thanks to sensors, data analytics and AI. Real‑time monitoring can spot a defect before a whole batch is produced, saving material and time. Predictive maintenance alerts prevent costly machine breakdowns, and digital twins let engineers test new alloy recipes virtually. If you run a small workshop, adopting a few cloud‑based tools can give you the same accuracy that large plants have had for years.

New alloys are also a big part of the future metal story. High‑entropy alloys, for example, combine several metals in equal parts to create material that’s tougher and more heat‑resistant than anything made with a single element. These are already finding homes in aerospace and electric‑vehicle components where weight and durability matter most.

Recycling is getting a high‑tech upgrade, too. Advanced sorting systems use AI to separate metals by composition faster than a human ever could. This not only boosts the amount of scrap that can be reused but also reduces the need for fresh ore mining, which is a win for the environment and the bottom line.

Supply chains are becoming more transparent. Blockchain‑based ledgers let buyers trace the origin of every kilogram of metal, confirming it meets sustainability standards. This builds trust with customers who care about where their products come from and helps companies avoid penalties for non‑compliance.

What does all this mean for you? If you’re buying metal, you’ll soon have more data to choose products that fit your performance and sustainability goals. If you’re a manufacturer, investing in electrification, AI tools and new alloy research will keep you competitive as regulations tighten and customers demand greener products.

In short, the future metal landscape is about cleaner production, smarter factories and innovative materials. The changes are already happening, and the next few years will see them become the new normal. Stay curious, keep an eye on emerging tech, and you’ll be ready for the metal of tomorrow.

The Emerging Future of Steel: Innovations and Developments

As the world continues to industrialize and innovate, the demand for steel is undergoing significant changes. This article explores the evolving role of steel in the future, particularly how advancements in manufacturing processes are shaping its potential. Discover the revolutionary materials and technologies that promise to redefine steel's place in the industrial world. By looking at current trends and future predictions, we gain insight into how these transformations will impact both industrialists and everyday consumers.