Ever wondered how your favorite snacks go from farm to packet? That’s where food units come in. These are the heart of the food processing world—places where basic ingredients are cleaned, sorted, mixed, cooked, packed, and finally shipped out. If you look close enough, most of what you eat has passed through some kind of food processing unit before it hits store shelves.

Food units aren’t just big factories. They come in all shapes and sizes—tiny local setups making chutney for the neighborhood, or massive plants churning out biscuits for the whole country. Their job is to handle food safely and efficiently, taking care of everything from washing veggies to sealing cans. Every step inside a food unit is tracked, measured, and designed to keep food fresh and safe. If you eat packaged food, you rely on these systems every single day.

- The Real Meaning of Food Units

- Different Types of Food Processing Units

- Key Equipment and Technology Inside Food Units

- Food Safety and Quality Control

- Trends Shaping Modern Food Units

- Tips for Managing a Successful Food Unit

The Real Meaning of Food Units

When you hear the term food units, think of them as the places or set-ups where food ingredients get transformed into forms we can actually eat or use. These aren’t just random buildings—they’re organized spaces with a purpose. The main job is to take rice, wheat, milk, veggies, meat, or other raw materials and turn them into market-ready products like bread, cheese, chips, or frozen meals.

A food unit can be a large-scale plant producing thousands of packs a day or a mid-sized workshop preparing fresh meals for local delivery. No matter the size, every food unit follows a series of steps: receiving raw materials, cleaning, sorting, processing, packing, and storing. Some units focus on just one product—like a dairy processing unit for making paneer—while others handle a whole bunch, like those multipurpose kitchens in big cities.

Why do food units matter? First, they make sure products meet everyday needs—think about how bread, instant noodles, or biscuits are always in stock in stores. Second, they save time for the consumer by doing the tough stuff: washing, peeling, cooking, and packing. And third, food units play a big part in food safety. They use strict guidelines to prevent spoilage and contamination.

- India has over 40,000 registered food processing units according to FSSAI (Food Safety and Standards Authority of India).

- Most popular food units include bakeries, dairy units, snack factories, rice mills, and frozen food plants.

- Units can be specialized (making only ice cream, for example) or diversified (handling everything from pickles to ready meals).

In short, food units are the backbone that connects farms and factories to your fridge and dining table. Every cookie, juice, or packet of pasta you grab has likely made its pitstop at a food unit before reaching you.

Different Types of Food Processing Units

Not all food processing units do the same thing. Each one is built for a different job in the food supply chain. Knowing the main types helps you understand how your food actually gets made, packaged, and sent to stores.

Let’s break down the most common types you’ll see:

- Primary food units: Here’s where it all starts. These units handle just-harvested crops, raw meat, or milk. They sort, clean, and sometimes chop or chill raw ingredients but don’t create finished grocery products. Think rice mills or meat packing plants—they prepare ingredients for further processing.

- Secondary food units: These transform cleaned raw ingredients into the products you actually buy, like bread, chips, yogurts, or sauces. Baking factories, dairies, and fruit jam plants all fit here. They do mixing, baking, cooking, fermenting, and more. Quality control is big in these places.

- Tertiary food units: This is where ready-to-eat or instant food gets prepped. Frozen meals, instant noodles, and packed snacks are made here. The focus is on convenience, longer shelf-life, and attractive packaging.

Some places cover all three steps under one roof, but usually, each unit sticks to its main job to keep things smooth and cost-effective.

Here’s a look at how these food processing units add value to our food:

| Type of Unit | Main Function | Example Product |

|---|---|---|

| Primary | Initial cleaning, sorting | Dehusked rice |

| Secondary | Transforming ingredients | Bread, cheese, tomato sauce |

| Tertiary | Convenience food creation | Frozen pizza, cup noodles |

If you’re starting a food unit, you need to pick the right type based on what you want to make and where you fit in the market. Each type comes with its own rules, equipment, and safety needs. Don’t forget to check local laws too—inspection standards can change a lot between different food processing levels.

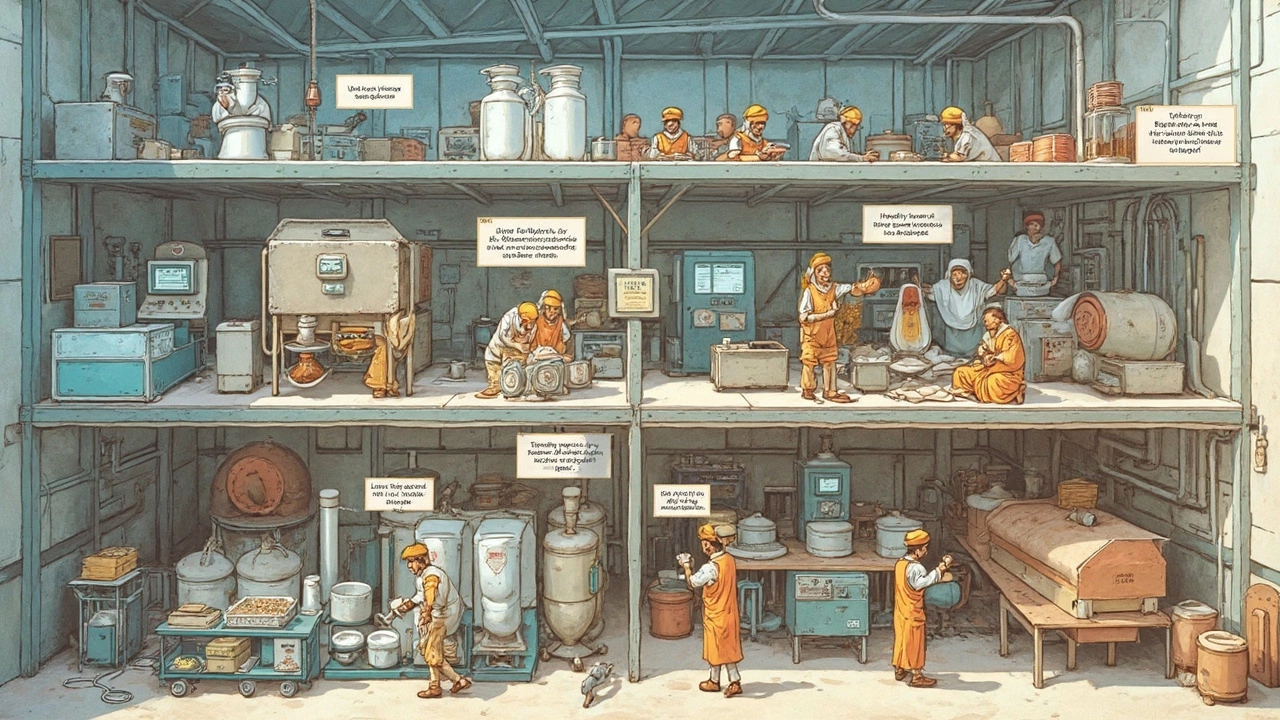

Key Equipment and Technology Inside Food Units

Step into any busy food unit and you’ll find a whole lineup of machines working together. Each one has a job, and skipping even a single piece can throw things off. It’s not all about big, noisy gadgets either—some of the most important equipment wouldn’t even fill your backpack.

Here's what you’ll spot most often in a modern food processing setup:

- Washers and Sorters: Everything starts with getting rid of dirt and stuff you don’t want. Machines sort tomatoes by size, pick out bad grains, and wash off pesticides from veggies. No one wants muddy chips.

- Grinders and Mixers: Turning wheat into flour or blending different spices? Grinders and mixers do the heavy lifting. They save time and give you even texture, batch after batch.

- Boilers and Ovens: Cooking at scale is no joke. Industrial boilers and ovens fire up nonstop to bake, steam, or boil by the ton. Forget about your home cooker—these things can make dinner for a thousand in an hour.

- Conveyors: Ingredients move through the line on conveyor belts, cutting down the carrying and speeding up the process. Everything’s automatic—less lifting, fewer mistakes.

- Packaging Machines: Ask anyone in food manufacturing, the right package keeps food fresh and safe from bugs or germs. Machines fill, wrap, seal, and even print dates and QR codes. You get clean, clear labels and longer shelf life.

- Metal Detectors and Quality Scanners: These check for stuff that shouldn’t be in your food—like bits of metal or plastic. If there’s a problem, the belt stops and the bad item is kicked out.

Fancy tech is everywhere too. Lots of food units now use sensors to track temperature and humidity, which is huge for snacks, sweets, and bread. Computer systems log every step, making it easy to trace when something goes wrong.

| Equipment | Main Use |

|---|---|

| Washer/Sorter | Cleaning and sorting produce |

| Grinder/Mixer | Breaking down grains, mixing ingredients |

| Industrial Oven | Baking and cooking large quantities |

| Packaging Machine | Sealing and labeling food products |

| Metal Detector | Screening for contaminants |

So why does all this technology matter? Better machines mean safer, tastier, longer-lasting food with fewer mistakes. If a line goes down, it’s easy to trace the problem using computer logs. Plus, with smart machines, even smaller food units can punch above their weight and compete with the big players. Every tasty packaged snack owes a lot to these unsung heroes.

Food Safety and Quality Control

If there’s one thing every food processing unit must nail, it’s keeping food safe. Whether you’re making snacks or running a full-blown factory, one mistake can mess up a whole batch, cost a lot of money, or even hurt someone. That’s why most countries have strict rules for food units—think FSSAI in India or FDA checks in the US. They're watching how food is stored, cooked, cooled, and packed, right down to how often workers wash their hands.

Good quality control isn’t just about passing inspections. It’s about making stuff people actually want to eat—fresh, clean, tasty food that looks and smells right every single time. Top food units set up checkpoints from the minute raw food arrives until the last box leaves the plant. Here’s what really goes on:

- Raw Material Checks: They test for stuff like pesticides, germs, or anything not supposed to be there. No shortcuts.

- Clean Equipment: Machines get sanitized on a schedule, and there’s a record for every wash.

- Worker Hygiene: Hairnets, gloves, and clean uniforms aren’t just for show. Some units even use footwear dips or hand sanitizing stations before anyone touches food.

- Temperature Control: Dairy, meat, and even veggies need certain chill or heat levels, tracked by sensors around the clock.

- Sample Testing: Finished products are tested for taste, crunch, color, or shelf life. If anything’s off, they trace the problem before anything gets shipped.

Check out this table—it shows common problems caught during quality control in Indian snack units in 2024:

| Issue Detected | Frequency | Action Taken |

|---|---|---|

| Excess oil in snacks | 15% | Adjusted fryer temperature |

| Foreign particles | 7% | Re-screened raw materials |

| Low salt content | 9% | Calibrated seasoning machines |

If you’re setting up a food unit or even working in one, don’t cut corners on safety. The tiniest mistake can be a disaster. Follow the rules, double-check your steps, and remember—if you wouldn’t eat it, don’t ship it.

Trends Shaping Modern Food Units

Right now, food units are changing fast, and there’s a good reason behind the upgrades. With more focus on food safety, sustainability, and speed, companies are doubling down on smart tech and new processes. These aren’t just buzzwords—they’re forcing everyone, from small producers to mega factories, to rethink how they handle food.

Smart automation is everywhere. Instead of relying on lots of hands, factories use machines with sensors and AI that can sort, pack, or even taste food faster and more accurately than people. For example, a lot of snack makers now scan every chip using high-speed cameras, chucking out the burnt pieces instantly. Talk about high standards!

Cleanliness and safety have taken center stage, especially after recent food scares. Most food processing setups use real-time monitoring systems that check temperature, humidity, and cleanliness non-stop. Data loggers and connected thermometers are as common as spatulas now. Mess up the numbers, and production stops until things look right again. Here’s a quick look at three popular tech upgrades in food processing units:

| Trend | What it Does |

|---|---|

| Automation | Saves time, cuts mistakes, and keeps people away from dangerous machines |

| IoT Sensors | Tracks cleanliness, temperature, shipment—keeps product safe |

| Traceability Software | Quickly finds and fixes problems when something goes wrong |

Eco-friendly moves are everywhere, too. Factories are switching to solar power, recycling water, and using less plastic for packaging. You’ll see labels touting ‘green manufacturing’ and ‘minimal waste’ like badges of honor. In fact, some plants in India are running almost entirely on renewable energy, turning what used to be an expensive switch into cost savings.

And here’s something everybody loves—custom foods. Thanks to smart tech, it’s easier for food processing companies to make foods for special diets, like gluten-free or vegan, without separate factories. Machines just swap recipes on the fly. This is opening up the market for all sorts of small-batch, specialty products.

Finally, food safety rules are getting stricter. Easy digital logs and automated reporting help units pass audits with less hassle. There’s less paperwork, more traceability, and better peace of mind for everyone—from workers to everyday shoppers.

Tips for Managing a Successful Food Unit

Running a food unit isn’t just about pushing products out the door. To stay ahead, you’ve got to be laser-focused on quality, efficiency, and safety. Whether you’re running a small setup or a big food processing facility, a few solid moves can make a real difference.

- Follow strict hygiene routines: Food safety comes first. Make sure your team wears gloves, hairnets, and clean uniforms. Clean machines and workspaces daily, and set up regular deep-cleaning schedules to wipe out hidden germs.

- Monitor quality at every step: Don’t wait till the end to check products. Set up quality checkpoints from raw materials to final packaging. Some successful food units use digital tracking systems to spot problems fast and keep mistakes from slipping through.

- Train your staff often: Even with the best machines, untrained hands can cause slip-ups. Hold short, focused training sessions on everything from operating equipment to food handling practices. Keep things practical and cover new rules as soon as they come in.

- Keep equipment running smoothly: Don’t wait for a breakdown. Regularly check machines for wear and tear. Log maintenance dates, update parts when needed, and don’t skip the small fixes—a minor fault can mess up a whole batch.

- Reduce waste, boost profits: Watch how much scrap you create and set up routines to recycle or repurpose leftovers. Some plants save up to 20% in costs just by streamlining waste management and recycling what’s possible.

- Go digital where you can: Modern food processing units use smart sensors and apps to track batch times, ingredient usage, and even staff performance. It’s not about fancy tech, but about seeing problems early and fixing them before they become expensive.

| Area | Potential Savings (%) |

|---|---|

| Reducing Product Waste | 18% |

| Efficient Equipment Maintenance | 12% |

| Digital Workflow Tracking | 8% |

Another smart move: stay updated with food safety laws. The rules can change fast—especially with new tech and changing consumer demands. Following the latest standards helps you avoid fines, keeps customers safe, and builds a good name in the market. Bottom line? A successful food unit mixes good people, clean spaces, and smart tools. Do these well, and your products are more likely to win trust and repeat buyers in a crowded market.