Toyota Engine Fuel Efficiency Calculator

Calculate Your Fuel Costs

See how different Toyota engines manufactured at the Bidadi plant compare in fuel efficiency and cost for your driving habits.

Results

Your annual driving distance: 15,000 km

Current fuel price: ₹95.00/L

Engine type selected: 1.5L D-4D Diesel

Fuel Efficiency

1.5L D-4D Diesel: 22.5 km/L

Fuel Efficiency

2.0L Petrol: 16.2 km/L

Fuel Efficiency

Hybrid: 28.3 km/L

Annual Fuel Cost

1.5L Diesel: ₹6,667

Annual Fuel Cost

2.0L Petrol: ₹9,259

Annual Fuel Cost

Hybrid: ₹5,300

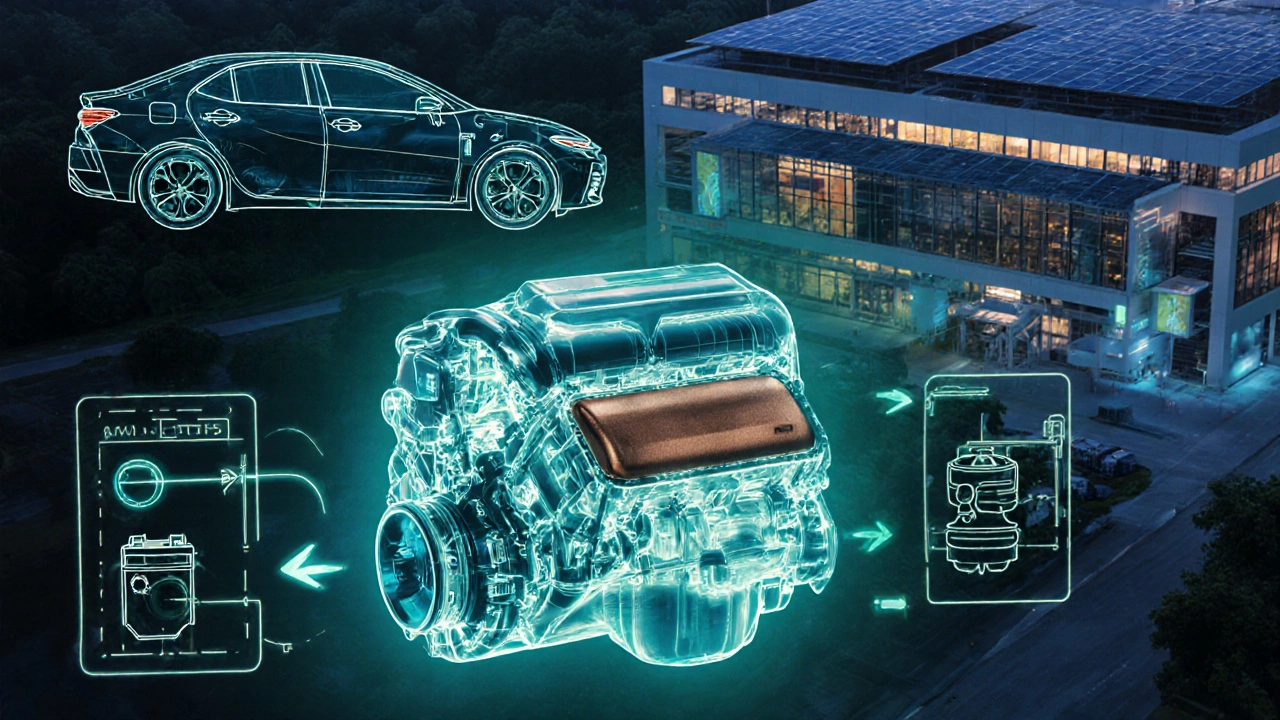

When you hear the name Toyota (the Japanese automotive giant), you probably picture a sleek sedan rolling off a Japanese assembly line. But the reality in India is far more interesting - the engines that power many Toyota models on Indian roads are actually built right here, under a local partnership and at a dedicated engine plant. This article unwraps who makes the engine for Toyota in India, why it matters, and what the future looks like for those power‑units.

Toyota’s Manufacturing Footprint in India

Toyota entered the Indian market in 1997 through a 50:50 joint venture with the Kirloskar Group, creating Toyota Kirloskar Motor Ltd. (TKM), the entity that handles sales, service and local production of Toyota vehicles. While TKM initially focused on assembling cars, the company quickly realized that a reliable, locally sourced engine was essential for cost‑competitiveness and meeting Indian emission norms.

The Bidadi Engine Plant: Heart of Toyota’s Indian Power‑Units

In 2011 Toyota inaugurated its first dedicated engine facility in Bidadi (a town near Bengaluru, Karnataka). The plant, officially known as the Toyota Engine Manufacturing Plant (TEMP), spans over 30 hectares and employs around 2,500 skilled workers. Its primary mission is to crank out the 1.5‑litre and 2.0‑litre diesel and petrol engines that equip models such as the Etios, Corolla, and the Innova Crysta.

What Exactly Is Produced at Bidadi?

- 1.5‑litre D‑4D diesel engine - the workhorse for the Etios Diesel and the early Innova.

- 2.0‑litre 2GR‑FSE petrol engine - found in the Corolla and the newer Innova Crysta.

- Hybrid power‑train modules - started in 2023 for the Corolla Hybrid, combining a gasoline engine with an electric motor.

All these engines are built to meet India’s Bharat Stage VI (BS‑VI) emission standards, which are on par with Euro 6. The Bidadi plant’s production capacity is roughly 200,000 engine units per year, enough to supply both the domestic market and a few export orders to neighboring South Asian countries.

Other Players in Toyota’s Engine Supply Chain

While Bidadi is the flagship facility, Toyota’s Indian engine ecosystem also includes a few strategic partners:

- Mazda Motor Corporation (Japan’s sister automaker, linked through a historic joint‑development agreement) - supplies the 2.0‑litre SKYACTIV‑G gasoline engine that powers certain Toyota Corolla variants exported to India.

- Denso Corporation (Toyota’s long‑time parts supplier) - provides fuel‑injection systems, turbochargers, and electronic control units that are integral to the Bidadi‑built engines.

These collaborations give Toyota the flexibility to fine‑tune power‑output, fuel‑efficiency, and emissions without having to re‑tool the Bidadi line for every new engine family.

Why Local Engine Production Matters for India

There are three big reasons why having a home‑grown engine factory is a win‑win for both Toyota and the Indian automotive scene:

- Cost Savings - Import duties on fully built engines can reach 30 %. By manufacturing locally, Toyota cuts down on tariff exposure and passes savings to shoppers.

- Regulatory Compliance - BS‑VI norms demand sophisticated after‑treatment technologies. Local production lets Toyota adapt quickly to rule changes without waiting for overseas supply chains.

- Job Creation & Skill Development - The Bidadi plant has generated over 2,500 direct jobs and numerous ancillary roles in casting, machining, and logistics, bolstering Karnataka’s manufacturing ecosystem.

Future Outlook: Hybrid and Electric Power‑Units

India’s push toward electrification is reshaping how manufacturers think about engines. Toyota has announced a multi‑phase roadmap:

- 2025 - Full‑scale production of the Corolla Hybrid’s 1.8‑litre Atkinson‑cycle engine at Bidadi.

- 2027 - Introduction of a plug‑in hybrid variant for the Innova, combining the 2.0‑litre engine with a larger battery pack.

- 2030 - A pilot “e‑engine” unit that will act as a range‑extender for future electric‑focused models.

These plans show that the Bidadi plant will evolve from a pure‑engine factory into a hybrid‑power‑module hub, aligning with India’s target of 30 % electric vehicle sales by 2030.

Comparison of Engine Suppliers for Toyota in India

| Supplier | Primary Engine(s) | Location | Annual Capacity | Key Strength |

|---|---|---|---|---|

| Toyota Kirloskar Motor (Bidadi) | 1.5 L D‑4D Diesel, 2.0 L 2GR‑FSE Petrol, Hybrid Modules | Karnataka | ~200,000 units | Full control, BS‑VI compliance, local job creation |

| Mazda Motor Corporation | 2.0 L SKYACTIV‑G Petrol (exported) | Japan | ~150,000 units (global) | Advanced combustion tech, fuel‑efficiency |

| Denso Corporation (component supplier) | Fuel‑injectors, turbochargers, ECUs | Multiple Indian locations | N/A (component level) | High‑precision electronics, OEM‑grade reliability |

Common Questions About Toyota Engines Made in India

Frequently Asked Questions

Where is the Toyota engine plant located?

The primary engine plant is in Bidadi, Karnataka, about 30 km south of Bengaluru.

Which Toyota models use engines built in India?

The Etios, Corolla, Innova Crysta, and the hybrid‑version of the Corolla all rely on locally manufactured power‑units.

Does Toyota import any engines into India?

A few niche models, especially those using Mazda’s SKYACTIV‑G engine, are imported. The majority, however, are produced at the Bidadi facility.

How many people does the Bidadi plant employ?

Around 2,500 direct employees, plus thousands more in the surrounding supply chain.

What’s the roadmap for hybrid engines in India?

Toyota aims to start full‑scale hybrid engine production by 2025, expand to plug‑in hybrids by 2027, and explore range‑extender electric units by 2030.

Key Takeaways

- The engine that powers most Toyota cars in India is built by Toyota Kirloskar Motor at its Bidadi plant in Karnataka.

- Local production cuts costs, meets strict BS‑VI norms, and creates thousands of jobs.

- Strategic partners like Mazda and Denso supplement specific components or niche engine families.

- Hybrid power‑train manufacturing is ramping up, signalling a shift toward electrification.

If you’re tracking the Indian automotive supply chain, keep an eye on the Bidadi plant’s capacity upgrades and the upcoming hybrid rollout - they’ll shape the market for years to come.