Chemical Industry Production Comparison

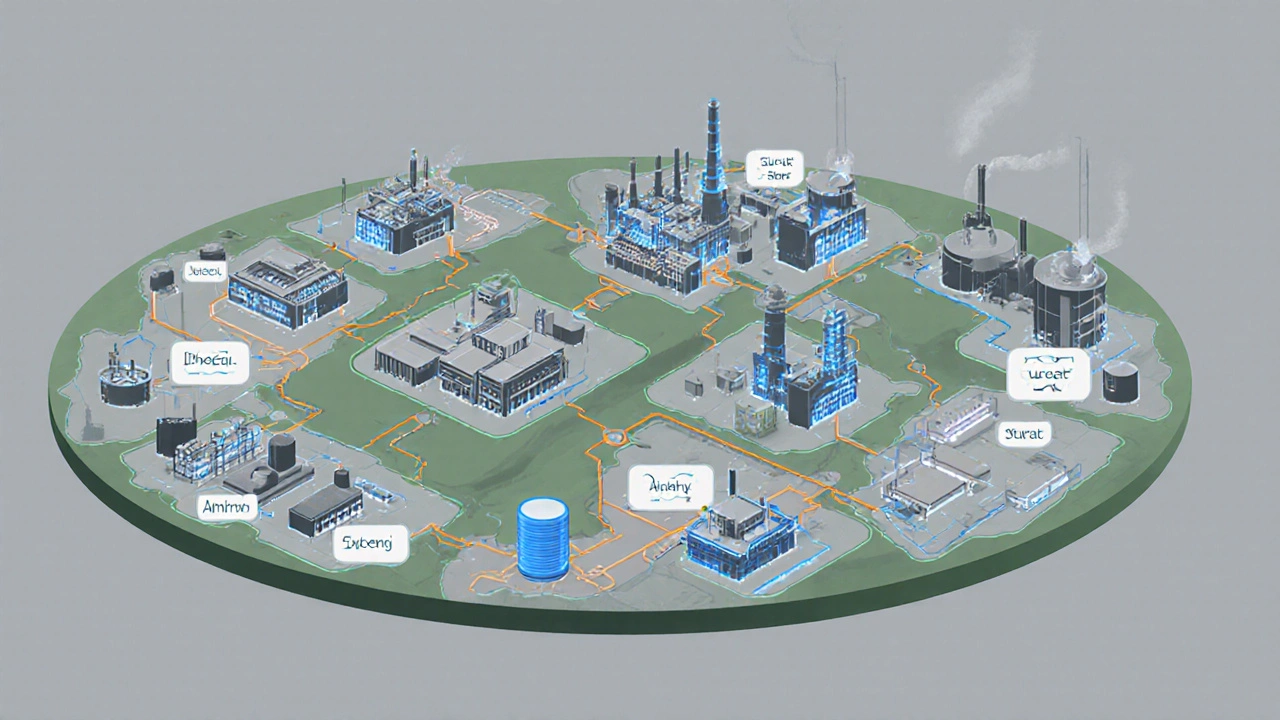

Compare India's Chemical Production Hubs

Gujarat produces over 40% of India's chemical output and handles 70% of chemical exports. Compare its production metrics with other regions to understand why it's the industry leader.

When you think of chemical manufacturing in India, one name stands out above all others - Gujarat. But not the whole state. The real heart of it? Dahej and Jamnagar in the Saurashtra region, and especially the Gujarat Chemical Industrial Cluster stretching from Vadodara to Surat. This isn’t just a cluster - it’s the largest concentration of chemical plants in South Asia, producing everything from basic inorganic chemicals to complex pharmaceutical intermediates and specialty polymers.

Why Gujarat? The Perfect Storm of Factors

Gujarat didn’t become India’s chemical capital by accident. It’s the result of decades of planning, infrastructure investment, and smart policy. The state has over 40% of India’s total chemical production capacity. Why? First, access to ports. Gujarat has nearly 40% of India’s coastline, with major ports like Mundra, Kandla, and Hazira handling over 50% of the country’s chemical imports and exports. Raw materials like naphtha, chlorine, and ethylene arrive by ship and get processed within hours.

Second, natural gas. Gujarat sits atop India’s largest onshore natural gas fields, especially in the Cambay Basin. Natural gas is the primary feedstock for producing ethylene, methanol, and urea - the building blocks of plastics, fertilizers, and solvents. Companies like Reliance Industries and LG Polymers built massive integrated complexes here because gas is cheaper and more reliable than importing it.

Third, government support. The Gujarat Industrial Policy offers land at subsidized rates, streamlined environmental clearances, and dedicated industrial corridors. The Dahej Special Economic Zone (SEZ) alone hosts over 80 chemical and petrochemical units, including global players like BASF, Dow, and LyondellBasell.

The Big Players: Who Runs the Show?

India’s top chemical manufacturers are clustered here. Reliance Industries operates the world’s largest single-site petrochemical complex in Jamnagar - a $65 billion investment producing 15 million tonnes of petrochemicals annually. That’s more than the entire chemical output of countries like Thailand or South Korea.

Then there’s Gujarat Alkalies and Chemicals Limited (GACL), based in Vadodara, one of Asia’s largest producers of caustic soda and chlorine. Their plant supplies over 30% of India’s chlorine demand - used in water treatment, PVC, and bleach production.

Smaller but critical are companies like Aarti Industries in Surat, which makes specialty dyes and intermediates for global pharma brands. Or Deepak Nitrite, headquartered in Gujarat, which exports over 80% of its nitro compounds to Europe and the U.S. These aren’t local players - they’re global suppliers, and they all chose Gujarat because of the ecosystem.

Dahej: The Chemical Powerhouse

If you had to pick one town that defines India’s chemical industry, it’s Dahej. Located on the Gulf of Khambhat, this 3,000-acre industrial zone is home to over 50 major chemical plants. The infrastructure is unmatched: dedicated pipelines for steam, gas, and wastewater; 24/7 power supply from dedicated substations; and even a private port just for chemical tankers.

Here, you’ll find plants making polyethylene, polypropylene, ethylene glycol, and acetic acid. One plant alone produces 1.2 million tonnes of ethylene oxide yearly - used in antifreeze, detergents, and polyester fibers. Another makes chlor-alkali products that feed into over 1,000 downstream industries across India.

Dahej’s real advantage? Integration. Unlike other regions where chemicals are shipped in from distant plants, here, one company’s waste becomes another’s raw material. Hydrogen from a refinery goes to a methanol plant. CO2 from ammonia production gets used in urea manufacturing. This circular system cuts costs, reduces emissions, and makes the whole zone more efficient than any standalone plant.

Other Chemical Hubs in India - And Why They Don’t Compare

People often mention Mumbai, Chennai, or Kolkata as chemical centers. They’re not wrong - but they’re shadows of Gujarat.

Mumbai has legacy chemical plants, mostly in the Thane-Belapur belt. But land is expensive, environmental regulations are strict, and ports are congested. Most new investments avoid it.

Chennai has a strong pharmaceutical chemical sector - companies like Dr. Reddy’s and Aurobindo source intermediates here. But they rely on Gujarat for bulk chemicals. Chennai makes fine chemicals; Gujarat makes the bulk.

Kolkata’s chemical industry is mostly old, family-run units producing basic acids and dyes. They lack scale, modern technology, and export capability. Many are shutting down.

The truth? No other region in India has the combination of feedstock access, port connectivity, industrial policy, and scale that Gujarat does. Even Maharashtra’s Navi Mumbai industrial belt - often touted as an alternative - produces only 12% of what Gujarat does.

What Gets Made Here? The Full Range

The chemical output from Gujarat isn’t just one thing. It’s a whole ecosystem:

- Basic chemicals: Chlorine, caustic soda, sulfuric acid, ammonia

- Petrochemicals: Ethylene, propylene, benzene, xylene

- Polymers: Polyethylene, polypropylene, PVC, polystyrene

- Specialty chemicals: Dyes, pigments, surfactants, pharmaceutical intermediates

- Fertilizers: Urea, ammonium nitrate, phosphatic fertilizers

- Agrochemicals: Pesticides, herbicides, fungicides

These aren’t just for domestic use. India exports over $40 billion worth of chemicals annually - and 70% of it comes from Gujarat. The U.S. imports 15% of its chlorine from here. The EU buys 30% of its specialty dyes from Surat-based manufacturers. China relies on Gujarat for ethylene glycol used in PET bottles.

Challenges and the Road Ahead

It’s not all smooth sailing. Water scarcity is a growing issue - chemical plants use millions of liters daily. Gujarat’s groundwater levels are dropping in industrial zones. Companies are now investing in zero-liquid discharge systems and seawater desalination plants.

Environmental concerns also linger. In 2020, a gas leak at a plant in Visakhapatnam caused national outrage. Gujarat’s regulators responded by tightening emission norms and requiring real-time monitoring. Today, 95% of major plants have online pollution sensors linked to state agencies.

The next big push? Green chemicals. Companies like Reliance are investing in bio-based ethylene and carbon capture. Gujarat is now home to India’s first pilot plant producing green methanol from renewable hydrogen. This isn’t just future talk - it’s happening now.

Final Answer: The City That Powers India’s Chemical Industry

So, which city in India is famous for the chemical industry? It’s not one city - it’s a region. But if you need to pick a single point on the map that represents the heart of it, that’s Dahej. It’s where the pipelines meet the ports, where gas turns into plastic, and where India’s chemical exports begin.

For anyone looking to source chemicals, invest in manufacturing, or understand India’s industrial backbone - Gujarat isn’t just a location. It’s the system.

Is Gujarat the only chemical hub in India?

No, but it’s by far the largest. Other regions like Mumbai, Chennai, and Kolkata have chemical plants, but they’re smaller, older, and lack the integrated infrastructure of Gujarat. Gujarat produces over 40% of India’s total chemical output and handles 70% of its chemical exports.

Which company has the biggest chemical plant in India?

Reliance Industries operates the world’s largest single-site petrochemical complex in Jamnagar, Gujarat. It produces 15 million tonnes of petrochemicals every year - more than most countries. The entire complex spans over 5,000 acres and includes refineries, crackers, and polymer plants all linked together.

What chemicals are made in Dahej?

Dahej produces a wide range of chemicals, including ethylene, propylene, polyethylene, polypropylene, ethylene glycol, acetic acid, chlorine, caustic soda, and methanol. It’s also home to plants making specialty chemicals for pharmaceuticals, dyes, and agrochemicals.

Why are chemical plants concentrated in Gujarat?

Gujarat has natural gas reserves, deep-sea ports, dedicated industrial zones with utilities like steam and power, government incentives, and a skilled workforce. The region also has a circular economy where waste from one plant becomes feedstock for another - cutting costs and emissions.

Are there environmental risks with so many chemical plants?

Yes, there are risks, especially around water use and emissions. But Gujarat has responded with strict regulations. Over 95% of major plants now have real-time pollution monitoring. Many have adopted zero-liquid discharge systems and are shifting to green hydrogen and bio-based feedstocks to reduce their footprint.