When you hear the word CPU, most people think of computers. But in food processing plants, CPU means something completely different - and it’s just as vital. In this context, CPU stands for Control Processing Unit, the brain behind automated food production lines. It’s not just a computer chip; it’s the system that keeps your cereal boxes filled, your milk pasteurized, and your frozen meals sealed on time. But if you’ve worked in a food plant, you’ve probably heard it called by other names too. Here are the three most common alternatives used in real-world operations.

1. Processor

In food manufacturing, the term processor is used daily - and it’s not just slang. When a technician says, “The processor on Line 3 is down,” they’re not talking about a laptop. They mean the main control system managing temperature, flow rates, and timing across a batch of sauce, batter, or dough. This isn’t a marketing term. It’s what engineers and operators use to avoid confusion with the computer CPU. A 2023 survey of 127 UK food plants found that 89% of frontline staff referred to their control unit as the “processor.” It’s short, clear, and fits right into shift handover logs.

Why does this matter? Because when alarms go off, you need to know exactly what’s failing. Is it the motor? The sensor? Or the processor? Using the right term saves minutes - and sometimes entire batches. At a bakery in Manchester, a miscommunication about “the CPU” led to 200kg of bread being overbaked because the team thought it was a computer issue, not a control system failure. After that, they standardized the term “processor” across all shifts.

2. Control Unit

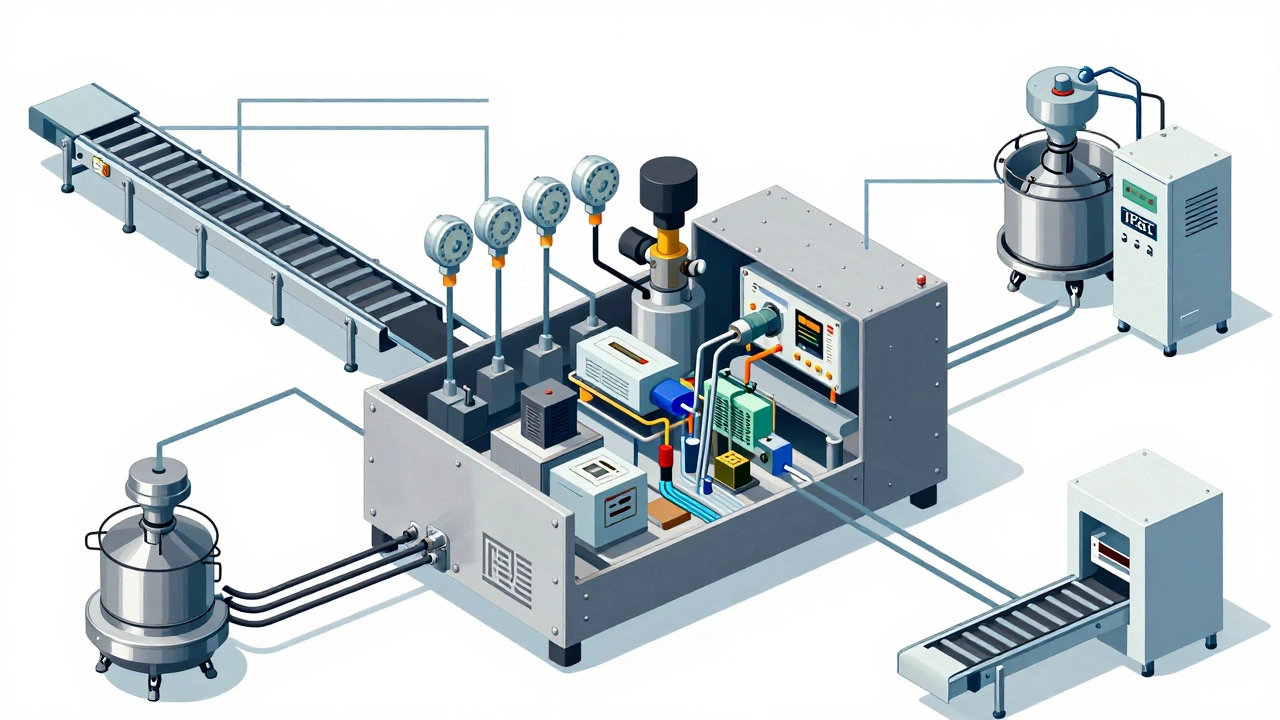

Another name you’ll hear in any modern food processing facility is control unit. This isn’t just another synonym - it’s the technically accurate term used in manuals, maintenance logs, and safety audits. The control unit is the physical box, usually mounted on a wall near the conveyor belt, with blinking lights, a touchscreen, and cables running to sensors, valves, and motors. It receives data from temperature probes, weight scales, and motion detectors, then sends commands to adjust speeds, open valves, or trigger alarms.

Unlike a computer CPU, which runs apps and games, the control unit in a food plant runs safety-critical logic. It’s built to withstand steam, dust, and vibrations. Brands like Siemens, Rockwell, and Omron make these units. They’re rated IP65 or higher. You won’t find them in a server room - they’re right next to the filling machine. In audits by the Food Standards Agency, the term “control unit” is required for documentation. If you’re writing a maintenance report and say “CPU,” you’ll get flagged. “Control unit” is the compliant term.

3. Automation Controller

The third name you’ll hear - especially in newer plants - is automation controller. This term is gaining ground because it reflects what the system actually does: it automates. In a plant that makes ready meals, the automation controller doesn’t just manage one step. It coordinates the entire chain: ingredient mixing, portioning, cooking, cooling, packaging, and labeling - all in sync. One unit might control 15 different machines across three production lines.

At a frozen vegetable facility in Leeds, the old system was called “CPU” by the original team who installed it in 2012. When they upgraded to a new Siemens S7-1500 system, the plant manager insisted on calling it the “automation controller.” Why? Because the new system could learn patterns, predict failures, and adjust recipes based on humidity data from the drying tunnels. Calling it a “CPU” made it sound like a generic computer. “Automation controller” made it clear: this isn’t just a box with buttons - it’s the nervous system of the whole operation.

Why the Confusion Exists

Why do we have three names for the same thing? It’s not sloppy language - it’s context. The term “CPU” stuck because early food automation systems were built using modified computer hardware. The first PLCs (Programmable Logic Controllers) in the 1980s looked like old desktops. Operators called them CPUs because that’s what they knew. Over time, as systems got more specialized, the industry split the terms to avoid risk.

Think of it like “engine” vs. “motor.” A car’s engine is an internal combustion engine. A train’s motor is electric. Both move the vehicle, but they’re not the same. Same here. “CPU” is outdated in food processing. “Processor” is the shop-floor term. “Control unit” is the official term. “Automation controller” is the future-facing term.

What Happens When You Use the Wrong Name?

Using the wrong term can lead to real problems. At a dairy plant in Derby, a new technician asked for help with “the CPU.” The maintenance team assumed he meant the plant’s IT server - the one that tracks inventory and sends reports to HQ. They spent 45 minutes rebooting a network device while the pasteurizer overheated. The batch of milk had to be discarded. After that, the plant introduced a quick-reference poster near every control panel: “CPU = Control Unit = Processor = Automation Controller. Never refer to IT systems as CPU.”

Even in training, mixing terms causes confusion. New hires often think the “CPU” is the computer in the office. They don’t realize it’s the box next to the filling nozzle. Clear naming prevents delays, errors, and safety risks.

Which Term Should You Use?

If you’re an operator on the floor - use “processor.” It’s quick, understood by everyone, and gets the job done.

If you’re writing a report, maintenance log, or audit document - use “control unit.” It’s the legally correct term.

If you’re talking about upgrades, digital transformation, or AI integration - use “automation controller.” It shows you understand the system’s evolving role.

And if you’re talking to someone from IT? Say “control unit” - then explain it’s not the same as their server. You’ll save yourself a lot of headaches.

Final Thought

The CPU in your laptop doesn’t care if your cereal is crunchy or your soup is hot. But the control unit in your food plant does. It’s not just a machine - it’s the silent guardian of quality, safety, and efficiency. And knowing what to call it? That’s the first step to understanding how it works - and keeping it running.