Manufacturing Product Viability Calculator

Match Your Workshop to the Right Product

This tool helps you identify which of the 8 in-demand small-scale manufacturing products are most viable for your workshop based on your available resources and capabilities.

Ever wondered which products you can actually make in a modest workshop and still see a line of orders? The good news is that 2025 is bursting with niches that reward quick‑turn, low‑cost production. Below you’ll find the most sought‑after items, why they’re hot, and how to turn them into a steady cash flow.

Quick Takeaways

- Focus on sustainability, customization, and tech‑enabled accessories.

- Three product groups (3D‑printed parts, eco‑friendly packaging, specialty foods) dominate demand.

- Start‑up costs range from $2,000 for simple food items to $25,000 for precision metal components.

- Key success factors: rapid prototyping, local sourcing, and clear niche targeting.

What drives demand in small‑scale manufacturing?

Understanding the why helps you pick a product that won’t fade in a few months. Three forces shape the market today:

- Consumer desire for personalization - People love items that feel made just for them, whether it’s a custom‑fit phone case or a hand‑stitched cushion.

- Heightened environmental awareness - Sustainable packaging and recyclable components are no longer nice‑to‑have; they’re expected.

- Rapid technology diffusion - Affordable 3D printers, CNC routers, and small‑batch food equipment let entrepreneurs launch fast.

When these trends intersect, demand spikes. The following list captures the sweet spots where small workshops thrive.

Top 8 In‑Demand Manufacturing Products

Each entry includes a brief market snapshot, typical investment, and the skill level you’ll need.

- 3D printed parts - From drone frames to customized orthopedic braces, the market grew 38% YoY. A mid‑range resin printer (~$4,500) plus a modest inventory of filaments can get you started. Design skills are a plus, but many clients supply CAD files.

- Custom furniture - Small‑batch, reclaimed‑wood pieces command premium prices ($300‑$2,000 per item). Initial tools (jigsaw, planer, sanders) cost about $2,200. The biggest hurdle is mastering finish work, which buyers judge instantly.

- Eco‑friendly packaging - Biodegradable boxes, compostable mailers, and reusable tote bags have seen a 42% surge as e‑commerce sellers chase greener branding. A simple die‑cut machine (~$3,000) and eco‑paper stock are enough to serve local brands.

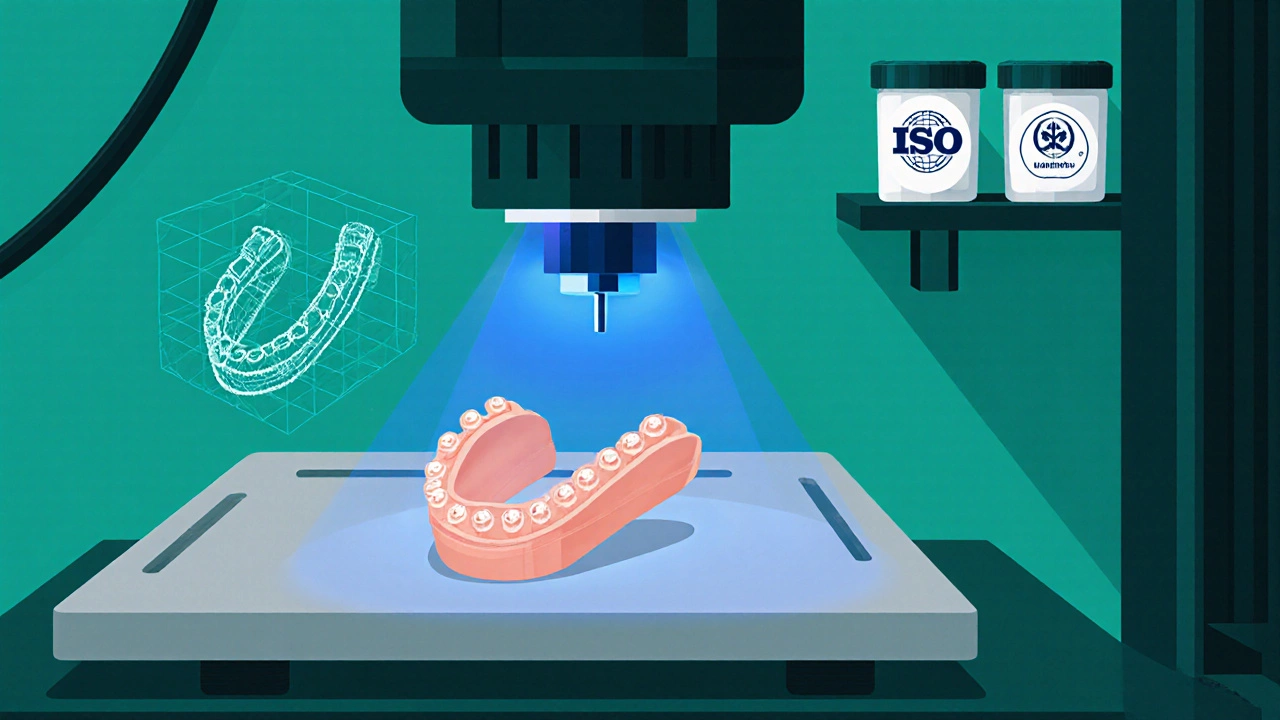

- Medical device components - Low‑volume components like silicone wristbands or plastic casings for wearables are in high demand due to rapid health‑tech innovation. Compliance (ISO13485) adds paperwork, but a cleanroom‑grade 3D printer (~$12,000) opens lucrative contracts.

- Specialty food items - Think artisanal hot sauce, vegan jerky, and gluten‑free snack mixes. The food‑processing market grew 24% in 2024, driven by online subscription boxes. A low‑cost dehydrator (~$800) and a certified kitchen can launch a brand quickly.

- Renewable energy components - Small solar panel brackets, wind‑turbine housings, and battery enclosures. Demand is rising as residential solar installations hit record levels. A CNC router (~$6,500) plus aluminum stock lets you serve installers.

- Plastic recycling products - Re‑grind pellets, 3‑D‑print filament made from post‑consumer waste, and molded trash‑bin accessories. Municipal recycling fees make these products cost‑effective for local governments.

- Handcrafted jewelry - Mixed‑metal cuffs, laser‑etched pendants, and resin‑filled stones. Online marketplaces like Etsy report a 15% growth in handcrafted accessories. A basic mini‑CNC (~$2,500) and a small inventory of metal sheets cover most designs.

How to evaluate if a product fits your workshop

Use this short checklist before you invest heavy equipment:

- Market size - Look for at least 5,000 potential buyers in your region or online.

- Profit margin - Aim for a 40%+ gross margin after raw material costs.

- Regulatory hurdles - Food, medical, and safety‑critical parts need certifications; factor in time and money.

- Tooling cost - Compare one‑off equipment price to projected yearly revenue.

- Skill match - If you lack a key skill, budget for training or partner with a designer.

Step‑by‑Step Guide to Launching a High‑Demand Product

- Validate the idea - Run a quick survey on niche forums or use Google Trends to confirm search volume.

- Prototype fast - Use a 3‑D printer or a simple hand‑tool to create a minimum viable product (MVP).

- Gather feedback - Offer the prototype to 10‑15 potential customers for free or at a discount.

- Refine the design - Incorporate feedback, improve tolerances, and finalize material choices.

- Set up production - Choose between batch‑size (e.g., 50‑unit runs) or on‑demand printing based on cash flow.

- Price strategically - Factor in material, labor, equipment depreciation, and a healthy profit buffer.

- Market launch - Leverage Instagram reels, TikTok demos, and niche community ads to drive early orders.

- Scale wisely - Re‑invest 30% of profit into better tooling or automation as demand stabilizes.

Comparison of the Top Product Categories

| Product | 2025 Demand Growth | Initial Investment (USD) | Skill Level Required | Regulatory Needs |

|---|---|---|---|---|

| 3D printed parts | 38% | 4,500-12,000 | Medium (CAD basics) | Low (except medical) |

| Custom furniture | 22% | 2,200-7,000 | High (woodworking) | Low |

| Eco‑friendly packaging | 42% | 3,000-8,000 | Low‑Medium | Medium (material certifications) |

| Medical device components | 30% | 12,000-20,000 | High (cleanroom practices) | High (ISO13485) |

| Specialty food items | 24% | 800-3,500 | Medium (food safety) | High (FDA/USDA) |

| Renewable energy components | 27% | 6,500-10,000 | Medium | Medium (UL listings) |

| Plastic recycling products | 19% | 2,500-5,000 | Low‑Medium | Low |

| Handcrafted jewelry | 15% | 2,500-6,000 | Medium (design) | Low |

Common Pitfalls and Pro Tips

Don’t ignore the cost of waste. Even a small scrap rate can erode margins on low‑priced items. Track material loss from day one.

Do invest in a reliable supplier for raw materials. A single delayed shipment can stall production and damage client trust.

Don’t over‑promise lead times. Small‑scale shops often face bottlenecks; a realistic 2‑week window builds credibility.

Do document every step in a simple SOP (standard operating procedure). It helps you train helpers and maintain quality as you grow.

Frequently Asked Questions

Which product needs the least upfront money?

Specialty food items often require the smallest capital - a basic dehydrator and a certified kitchen can start under $1,000.

Do I need certifications to sell eco‑friendly packaging?

Most biodegradable paper or compostable films need a material certification (e.g., ASTM D6400). It’s a simple test, but you’ll need a lab report for wholesale buyers.

Can I use a hobby‑grade 3‑D printer for medical components?

Only for non‑critical prototypes. Production parts require a printer that meets ISO13485 standards and uses biocompatible resins.

How much can I price a custom furniture piece?

Pricing depends on material, labor time, and design complexity. A good rule is material cost×3+labor, which typically lands you in the $300-$2,000 range for small‑scale pieces.

What’s the best way to find my first customers?

Start with niche online communities - Reddit, Facebook groups, and industry forums. Offer a limited‑time discount for early adopters and ask them to share feedback publicly.