Textile Business Startup Cost Calculator

Startup Cost Estimator

What's Included in Your Estimate

| Cost Category | Estimated Cost |

|---|---|

| Registration & Legal | ₹0 |

| Machine Costs | ₹0 |

| Raw Materials | ₹0 |

| Government Subsidies | |

| Total Investment Required | ₹0 |

Starting a textile business in India isn’t just about buying a sewing machine and opening a shop. It’s about understanding a $150 billion industry that employs over 45 million people, contributes 11% to industrial output, and accounts for nearly 12% of India’s total exports. If you’re thinking of jumping in, you’re not alone-but you need a clear plan. Many new entrepreneurs fail because they underestimate the complexity of sourcing raw materials, navigating government rules, or finding reliable buyers. This guide walks you through exactly what you need to do-no fluff, no theory, just real steps based on current regulations and market conditions in 2025.

Know Your Niche Inside Out

India makes everything from cotton khadi to high-end silk sarees, technical textiles for hospitals, and synthetic fabrics for global brands. You can’t be everything to everyone. Start by picking one product category you can master.

For example:

- Cotton yarn and fabric - High demand from domestic garment makers and small retailers.

- Handloom and traditional textiles - Strong export potential to Europe and the U.S., especially if certified under Geographical Indication (GI).

- Technical textiles - Used in automotive, medical, and agriculture sectors. Fast-growing segment with government support.

- Recycled polyester - Rising demand from global brands like H&M and Zara looking for sustainable supply chains.

Don’t pick what’s popular-pick what you can source, produce, and sell profitably. Visit local markets in Tiruppur, Surat, or Ludhiana. Talk to small wholesalers. Ask: What’s in demand? What’s oversaturated? What’s hard to find?

Register Your Business and Get Legal Compliance

You can’t legally operate without proper registration. Here’s what you need in 2025:

- Business structure - Choose between Sole Proprietorship, LLP, or Private Limited Company. Most small textile units start as Sole Proprietorship for simplicity.

- Udyam Registration - Free and mandatory for MSMEs. You’ll get a Udyam Registration Number (URN) and access to subsidies, credit guarantees, and easier loan terms. Apply at udyamregistration.gov.in.

- GST Registration - Required if your annual turnover exceeds ₹40 lakh (₹20 lakh for special category states).

- IEC Code - If you plan to export, get an Import-Export Code from DGFT. It takes 7-10 days and costs ₹500.

- Factory License - Needed if you have 10+ workers using power or 20+ without power. Apply under the Factories Act, 1948.

Many new owners skip Udyam Registration and later regret it. Without it, you can’t apply for government schemes like the Technology Upgradation Fund Scheme (TUFS) or get priority in public tenders.

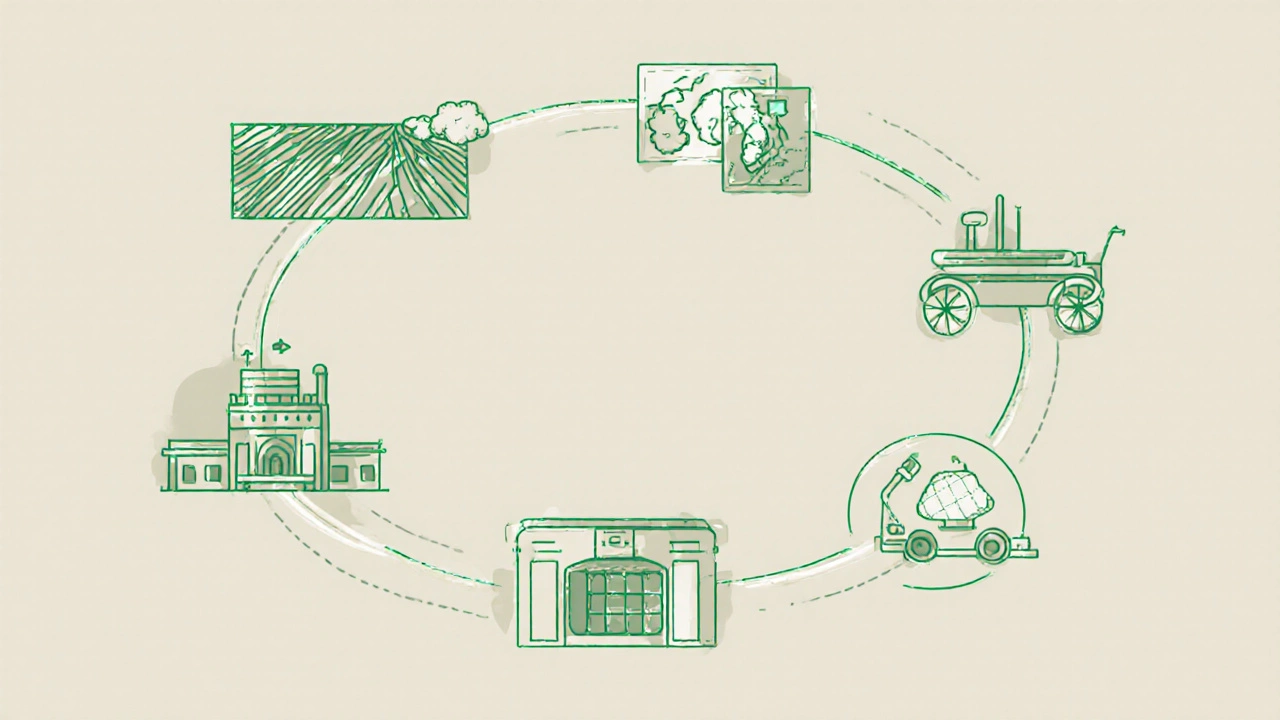

Find Your Raw Material Supply Chain

Textile production starts with fibers. In India, you have three main sources:

- Cotton - Major growing states: Maharashtra, Gujarat, Telangana. Buy directly from mandis (agricultural markets) or through cooperatives like Cotton Corporation of India.

- Yarn - Surat, Tiruppur, and Ahmedabad are top hubs. Many small units buy yarn instead of spinning their own to save on capital.

- Synthetic fibers - Polyester and nylon are mostly imported from China or sourced from Gujarat-based manufacturers like Reliance Industries.

Don’t rely on one supplier. Build relationships with at least two or three. Ask for samples, check quality consistency, and negotiate payment terms. Many small textile units fail because they run out of material mid-production.

Pro tip: Use the Textile Committee of India’s online portal to find registered raw material suppliers. It’s free and updated monthly.

Choose the Right Machinery and Setup

You don’t need a factory full of machines to start. Many successful textile businesses begin with just a few key machines:

- Spinning machines - For turning cotton into yarn. Cost: ₹5-15 lakh per unit.

- Weaving looms - Handloom (₹15,000-₹50,000) or power loom (₹3-8 lakh). Power looms are faster but need more electricity.

- Dyeing and printing units - If you’re making printed fabrics, you’ll need a dyeing vat, screen printing machine, or digital printer. Digital printers cost ₹10-25 lakh but reduce waste and offer custom designs.

- Finishing machines - For washing, shrinking, and pressing fabric.

For beginners, start with a small power loom unit (5-10 machines) and outsource dyeing. That keeps your initial investment under ₹15 lakh. Many entrepreneurs in Tiruppur start with just 3-5 looms and scale as orders grow.

Look for second-hand machines from closed units. Platforms like IndiaMART and TradeIndia list used textile machinery with warranty options.

Apply for Government Schemes and Subsidies

India offers serious financial support for textile startups. Don’t leave free money on the table.

- Technology Upgradation Fund Scheme (TUFS) - Up to 15% subsidy on new machinery, capped at ₹10 crore. You can use this for automation, energy-efficient motors, or digital printing.

- PM Mega Integrated Textile Regions and Apparel (MITRA) Parks - If you’re setting up in a designated MITRA zone, you get land at low cost, common infrastructure, and tax breaks.

- Interest Subvention Scheme - Get 5% interest subsidy on loans up to ₹2 crore from banks.

- Export Promotion Capital Goods (EPCG) Scheme - Import machinery duty-free if you commit to exporting 6x the value of imported goods in 8 years.

Apply through your local District Industries Centre (DIC). They help with paperwork and connect you to scheme officers. Many small owners don’t know about these-don’t be one of them.

Build a Brand and Find Buyers

Production is only half the battle. You need customers.

Start locally: Approach small garment manufacturers, boutique stores, and online sellers on Instagram or Meesho. Offer samples. Ask for feedback. Build trust.

For exports, join trade fairs like:

- India Textile Week (Mumbai)

- India International Textile Fair (New Delhi)

- Texworld Paris or Heimtextil Frankfurt (if you can afford to travel)

Use platforms like Alibaba, Global Sources, and IndiaMart Export to list your products. Include high-quality photos, fabric specs ( GSM, thread count, shrinkage rate), and certifications (OEKO-TEX, GOTS).

Many small exporters fail because they don’t understand buyer expectations. A U.S. brand won’t buy from you unless you have a certificate of origin, test reports, and packaging compliance. Get these early.

Manage Quality Control and Sustainability

Buyers today care about two things: consistency and ethics.

Set up a simple quality check process:

- Test colorfastness with a washing machine and sunlight exposure.

- Check fabric strength with a tensile tester (cost: ₹20,000-₹50,000).

- Keep a batch log: date, supplier, machine used, worker ID.

Sustainability isn’t optional anymore. If you’re exporting to Europe or the U.S., you’ll need:

- GOTS (Global Organic Textile Standard) - For organic cotton products.

- OEKO-TEX Standard 100 - For chemical safety in dyes.

- Recycled Content Certification - If you use recycled polyester.

These certifications cost ₹50,000-₹2 lakh but open doors to premium buyers. Many Indian mills skip them-and miss out on 30-40% higher margins.

Scale Smart: From Small Unit to Growing Business

Once you’re making consistent sales, think about scaling:

- Upgrade from manual to semi-automatic looms.

- Invest in ERP software for inventory and order tracking (like Tally or Zoho Inventory).

- Partner with logistics firms like Delhivery or Blue Dart for faster delivery.

- Start your own brand on Amazon India or Myntra if you have unique designs.

Avoid the trap of expanding too fast. Many textile owners take loans to buy 20 new looms and end up with unsold stock. Grow based on confirmed orders-not dreams.

Track your numbers: Cost per meter, profit margin, lead time, return rate. If your margin is below 18%, something’s wrong-either your cost is too high or your price is too low.

Common Mistakes to Avoid

- Skipping documentation - No Udyam, no GST, no IEC? You can’t get loans or export.

- Buying cheap machines - Low-cost looms break down often. Downtime costs more than a better machine.

- Ignoring export rules - Wrong labeling or missing certificates = shipment rejection.

- Trying to do everything alone - Hire a part-time accountant or use a bookkeeping app. Time is your most valuable resource.

- Not testing demand - Don’t produce 5,000 meters of fabric before you’ve sold 500.

Textile is a slow-burn business. It takes 12-18 months to build a reliable customer base. Stay consistent. Keep improving. Don’t chase quick wins.

How much money do I need to start a small textile business in India?

You can start a small textile unit with ₹10-15 lakh. This covers 3-5 power looms, a basic dyeing setup, raw material for 3 months, and legal registrations. If you’re only doing handloom or embroidery, you can begin with as little as ₹3-5 lakh.

Can I start a textile business from home?

Yes, if you’re doing handloom weaving, embroidery, or printing on small scales. You’ll need a dedicated space, proper ventilation, and compliance with local municipal rules. But if you plan to use power looms or dyeing machines, you’ll need a registered small industrial unit.

Which state is best for textile manufacturing in India?

Tamil Nadu (especially Tiruppur) leads in knitwear and exports. Gujarat (Surat) dominates synthetic fabrics and power looms. Uttar Pradesh and Maharashtra have strong handloom clusters. Choose based on your product type and access to raw materials.

How do I get export orders for my textile products?

List your products on Alibaba and IndiaMart Export. Attend India Textile Week. Join the Export Promotion Council for Handicrafts or Textiles. Reach out to importers on LinkedIn with samples and test reports. Start with small orders-100-500 meters-to build trust.

Are there any training programs for textile entrepreneurs?

Yes. The Textile Ministry and National Institute of Fashion Technology (NIFT) offer free short-term courses on design, quality control, and export procedures. Check their websites or contact your local DIC for updates.

If you’re serious about starting a textile business in India, the time is now. The global demand for Indian textiles is rising, government support is stronger than ever, and technology has made production more accessible. But success doesn’t come from copying others-it comes from understanding your product, your customers, and your costs. Start small. Stay sharp. Build slowly. And don’t wait for perfect conditions-create them.